Maintenance plan (BCN3D Sigmax)

Everything you need to do to take care of your BCN3D Sigmax

Maintenance is a very important task to keep in mind every day in order to keep the printer in good condition and always performing at its maximum capabilities.

This article shows which activities have to be carried out to give the BCN3D Sigmax the proper maintenance and their frequency. Maintenance activities do not take much time and are not complicated. However, for those that need more attention, more detailed guidelines are provided to guide you through the process.

To help you with the maintenance of the printer, BCN3D has a maintenance kit for the printer with the tools necessary to do it. You can get this kit on our website: BCN3D Sigmax maintenance kit

Contents:

General maintenance

There are some recommendations when performing general maintenance, but there are some indications that you must always consider in order to extend your printer's lifespan.

A very important advice is to keep your printer always free of dust and operating in a dry and cool place. The BCN3D Sigmax has to operate in an environment at temperatures between 15 and 30 ºC and a relative humidity below 50%. Regarding the filaments, it is advised that the spools that are not currently in use should be always stored in an airtight container with a relative humidity below 50% (although this may vary for certain materials).

|

Activity |

Frequency |

Tools |

|

Clean the printer. |

Daily |

Cloth |

|

Remove filament leftovers spread inside the printer. |

Daily |

Vacuum cleaner Compressed air |

|

Remove filament inside the purge buckets by removing the buckets. |

Daily |

- |

|

Clean dust in hotend fans and cooling fans. |

Monthly |

Compressed air |

|

Update printer firmware. |

Check monthly on the BCN3D website. |

- |

Hotend care

Hotends are a very important part of your printer and the quality and reliability of your prints depend on them. We recommend taking care of them in order to extend their lifespan, that it’s estimated to be more than 1000 printing hours. This time depends on the type of material that is used and the amount of maintenance that is performed on them.

|

Activity |

Frequency |

Tools |

|

Check if the nozzle is clogged by doing a purge or checking for under-extrusion in the previous prints. |

Every print |

- |

|

Check if the hotend and cooler fan are working properly. |

Every print |

- |

|

Weekly or when switching materials |

Nylon filament |

|

|

Every 300 printing hours, after transportation or after changing hotend |

- |

|

|

Check if the hotend cables are correctly connected to the hotend electronic board (behind the print head). |

Every 300 printing hours or when changing hotend |

- |

|

Check if the screws that secure the hotend to the print head are not loose. |

Every 300 printing hours or when changing hotend |

Allen key |

|

More than 1000 printing hours |

Allen key, Scissors or cutting pliers and Hotend |

|

|

Clean the fans. |

Every 300 printing hours or when the fans has dust |

Vaccum cleaner, compressed air or brush and tweezers. |

Extruder motor maintenance

The extruder motors are responsible of pushing the filament through the hotends. Having the right amount of material at the tip of the nozzle depends on them. They are usually components that are moving all the time, so they need maintenance regularly.

|

Activity |

Frequency |

Tools |

|

Remove material shavings in the extruder gears. |

Weekly |

Compressed air |

|

Check bowden tubes and connections to the extruder motors. |

Every 300 printing hours |

- |

|

Check if the cables are correctly connected to the motor driver and the extruder motor. |

Every 300 printing hours |

- |

|

Tune the thumbscrew tensioner to adjust the pressure exerted by the drive gears onto the filament. |

Every 1000 printing hours |

|

|

Every 1000 printing hours |

- |

Keeping your Printing surface

The printing surface is a very delicate component of the printer that can break or degrade if not treated properly. Proper calibration and therefore good printing quality depends on the flatness and cleanliness of this surface. This is a component that has to be maintained every time you start a printing process. The estimated lifespan of this component is 500 printing hours, but it highly depends on the material used, the calibration, and the type of printing.

|

Activity |

Frequency |

Tools |

|

Clean the glass printing surface with warm water and soap. |

Before each print |

Spatula Cloth |

|

Weekly or after transportation |

- |

|

|

Check the glass printing surface for scratches. |

Every 300 printing hours |

- |

Motion system care

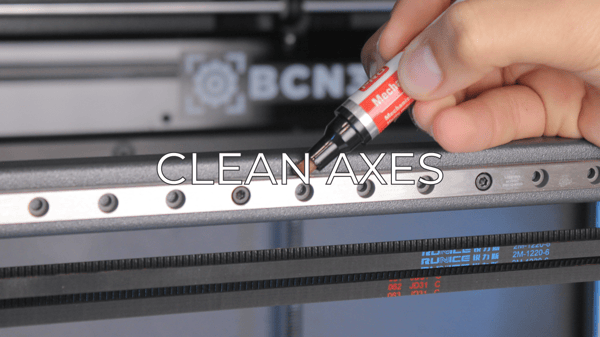

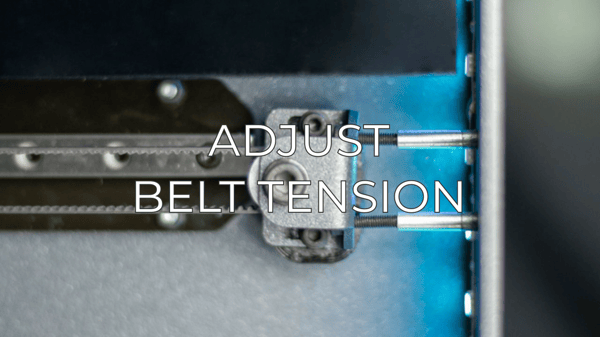

The motion system involves all the moving parts of your BCN3D Sigmax. This includes X, Y, and Z motors, linear guides, driver pulleys, belts, and so on. These parts are prepared and selected accordingly to last for a long time, however, some parts could get loose and affect the performance of your unit. We highly recommend performing easy maintenance tasks in order to keep your printer good as new.

|

Activity |

Frequency |

Tools |

|

Clean the axes linear guides and lead screws from material remains and dust. |

Weekly |

Cloth Compressed air |

|

Clean filament remains in motor shafts and belts. |

Weekly |

Cloth Tweezers Compressed air |

|

Check if the set screws on the motor and rod pulleys are tightened and aligned with the flat surface of the motor shaft. |

Every 300 printing hours |

Allen key |

|

Every 1000 printing hours |

Cloth Lubrication kit |

|

|

Check X/Y belts tension, and adjust if loose. |

Every 1000 printing hours |

Allen key Screwdriver |

|

Every 1000 printing hours |

- |

Firmware updates

At BCN3D we want you to have a great printing experience, to achieve this we are continually working to create new firmware upgrades for our printers.

To ensure that your printer is equipped with the latest features it is recommended to keep the firmware updated to the latest version.

To get more information about this check this guide: How to update the firmware (BCN3D Sigmax)

Forum community

Need more tips? Check out our forum community for more info.

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

| Parts | buy these parts | |

|

Nylon cleaning method | SKU 09001 |

|

Lubrication Kit | SKU 11105 |

|

Hotend (0.4 0.6 0.8 1mm) | SKU 10101, 10109, 10112 10113 |

RELATED ARTICLES |

|

|

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |