How to print BCN3D BVOH

Soluble thermoplastic, highly used as a support material for FDM 3D printers

What is BVOH?

|

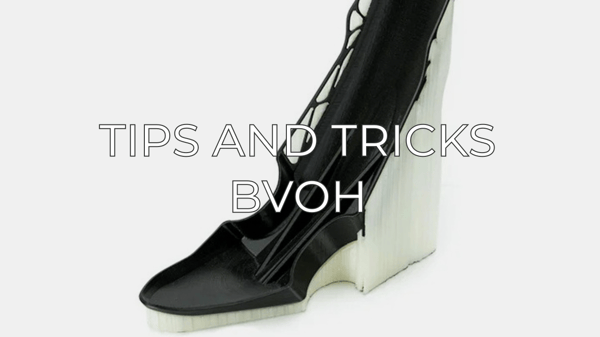

BVOH (Butenediol vinyl alcohol copolymer) is a water-soluble thermoplastic optimized for the FFF manufacturing process. Our BVOH extends the compatibility with most of BCN3D filaments and can be easily printed to create the support and then dissolved with ordinary water. |

BVOH supports help to get a better surface quality, orientate the part to get better mechanical properties, and even enable the printing of multi-component models and mechanisms with a quick dissolution and easy detachment.

You can buy BVOH in our shop: BCN3D BVOH

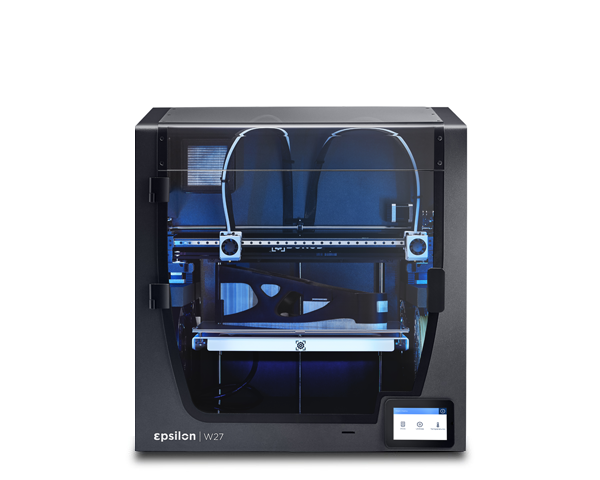

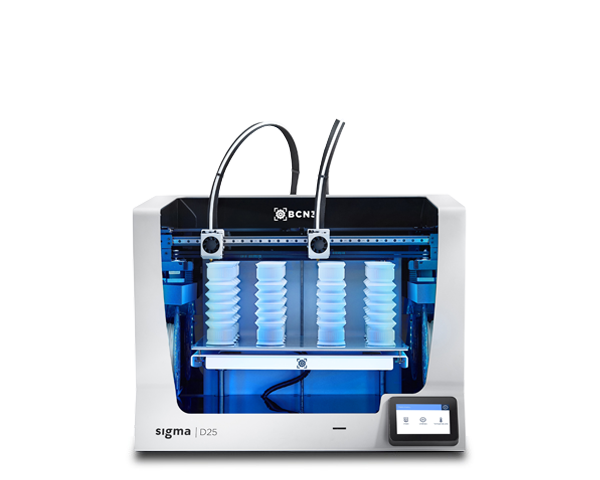

BVOH compatibility with BCN3D printers/hotends

| ✔ | ✔ | ✔ | ✔ | ✔ |

|

|

|

|

|

| 0.4 / 0.6 / 0.8 / 1 | 0.4 / 0.6 / 0.8 / 1 | 0.4 /0.8 | 0.4 / 0.6 / 0.8 / 1 | 0.4 / 0.6 / 0.8 / 1 |

Supported materials combinations

The BCN3D BVOH is compatible with the following BCN3D Filaments.

| Standard materials |

||||||||||||||

| PLA ✔ | TPU ✔ | PVA ✗ | BVOH ✔ | TPLA ✔ | PET-G ✔ | |||||||||

| Technical materials |

||||||||||||||

| ABS ✔ | PA ✔ | PP ✗ | ||||||||||||

| Composite materials |

||||||||||||||

| PAHT CF15 ✔ | PP GF30 ✗ | PET CF15 ✔ | 316L ✗ | 17-4 PH ✗ | ||||||||||

BVOH printing settings - 0.4 mm nozzle

| Extruder temperature | 190-210ºC |

| Build surface temperature | 45º- 90º |

| Speed | 20 mm/s |

| Retraction speed | 50 mm/s |

| Retraction distance | 7 mm |

| Cooling fan | 50% - 100% |

| Minimum layer height | 0.15 - 0.4 mm |

- Note: BCN3D lab develops specific configurations for each printer and material. Be sure that you are using the latest BCN3D Stratos version.

Build plate adhesion

|

Apply a thin and even Magigoo layer in order to have a good adherence between the printing surface and the print. The best option is to apply Magigoo when the printing surface is cold. Make sure that the support structures built with this material are in contact with the printing surface to avoid warping. |

|

Recomendations

Plastic absorbs humidity from the air. When the material is not in use, it is recommended to keep BVOH in a box or an airtight container with desiccant so it remains dry. The Smart Cabinet is your best friend when it comes to filament stocking. It maintains a suitable temperature and humidity conditions to ensure the best performance.

It is also recommended to unload the filament after a print job is finished to prevent it from absorbing moisture, as the part of the filament that stays out of the cabinet will be unprotected.

If you don't have the Smart Cabinet, make sure to unload the spool and store it as previously described.

Dry the BVOH during 4 hours at 70ºC to avoid issues related to the humidity like clogs or underextrusion.

Enabling the support interface when uses the BVOH as support material, helps to reduce the amount of material, reduces the printing time and in many cases reduces the cost of the printed part.

BVOH emits nearly no dangerous particles and fumes when it is being printed. However, we still recommend you print in a well-ventilated area to ensure a healthy environment.

Digital documentation of the BVOH

Here you can find and download the Technical data and the Safety data sheets of our BVOH:

|

|

|

| Send us your comments about this article |

|

||

RELATED ARTICLES |

|||

|

|

||