How to print with BCN3D PVA

A water soluble thermoplastic, widely used as support material for FFF 3D printers

What is PVA?

|

PVA (Polyvinyl alcohol) is a water-soluble thermoplastic, widely used as a support material for FFF 3D printers. Optimized for the FFF manufacturing process, our PVA is compatible with most of BCN3D filaments and can be easily printed for support and then dissolved with ordinary water. |

PVA supports allow a better surface quality to accommodate the part to enhance the mechanical properties and print multi-component models and mechanisms. Also, the PVA can be used to print sacrificial molds.

You can purchase PVA from our store: BCN3D PVA

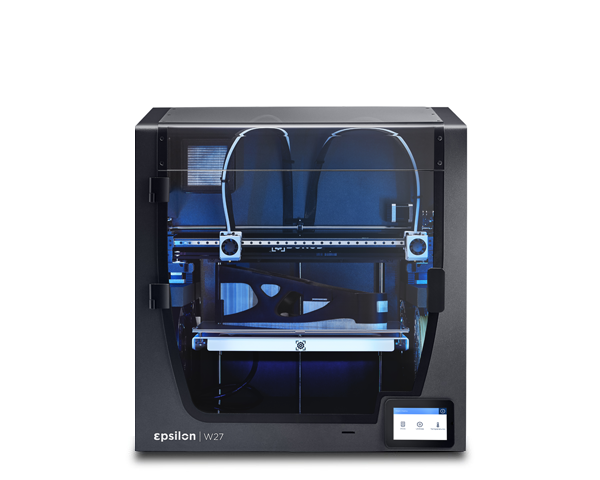

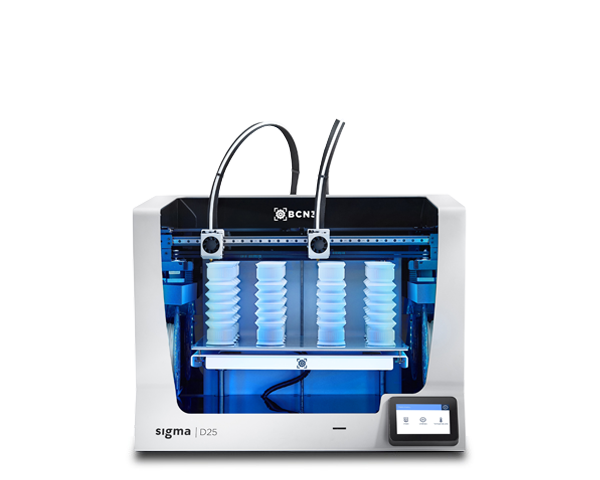

PVA compatibility with BCN3D printers / hotends

| ✔ | ✔ | ✔ | ✔ | ✔ |

|

|

|

|

|

| 0.4 / 0.6 / 0.8 / 1.0 | 0.4 / 0.6 / 0.8 / 1.0 | 0.4 /0.8 | 0.4 / 0.6 / 0.8 / 1.0 | 0.4 / 0.6 / 0.8 / 1.0 |

Supported materials combinations

BCN3D PVA is compatible with the following BCN3D Filaments.

| Standard materials |

||||||||||||||

| PLA ✔ | TPU ✔ | PVA ✔ | BVOH |

TPLA ✔ | PET-G |

|||||||||

| Technical materials |

||||||||||||||

| ABS |

PA ✗ | PP ✗ | ||||||||||||

| Composite materials |

||||||||||||||

| PAHT CF15 ✗ | PP GF30 ✗ | PET CF15 ✔ | 316L ✗ | 17-4 PH ✗ | ||||||||||

PVA printing settings - 0.4 mm nozzle

| Extruder temperature | 210ºC-230ºC |

| Build plate temperature | 45ºC - 60ºC |

| Speed | 25-30mm/s |

| Retraction speed | 40 mm/s |

| Retraction distance | 5 mm |

| Cooling fan | 50% |

| Minimum layer height | 0.15-0.4 mm |

- Note: BCN3D Lab develops specific configurations for each material and printer. Be sure to use the last BCN3D Stratos version.

Build plate adhesion

|

Apply a fine and even layer of Magigoo PRO glue to achieve a proper adhesion between the 3D printed part and the printing surface of your 3D printer in order to keep the part fixed. It is best to apply Magigoo when the printing bed is cool. Make sure that the support structure is strong and is in contact with the printing surface to avoid warping. |

|

Recommendations

Plastics absorb moisture from the air. If the material is not in use for extended periods of time, it is recommended to keep the PVA spools in a box or airtight container with desiccant to keep them dry.

Dry the PVA before printing, to avoid common issues related to the humidity like burned areas on the printed part or underextrusion.

PVA emits low levels of gasses and particles when printed. We recommend printing it in a well-ventilated area to ensure a healthy environment.

Enabling the support interface is one of the best ways to optimize the use of PVA for 3D printing. Also, helps to reduce the clogs in the hotend.

Digital documentation of the PVA

Here you can find and download the Technical data and the Safety data sheets of our PVA:

|

|

|

| Send us your comments about this article |

|

||

RELATED ARTICLES |

|||

|

|

||