Carriage parallelism is key to print in dual mode and avoid leaning and layer shifting in the Y-axis. If the carriage is not aligned, the X-axis is in high friction with the Y guides, which can damage the Y belts and can deform your prints.

To check the carriage parallelism follow the next steps:

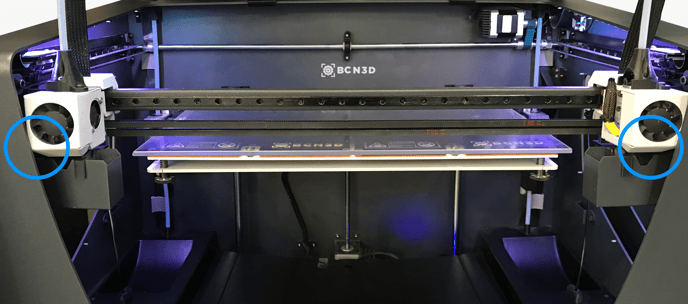

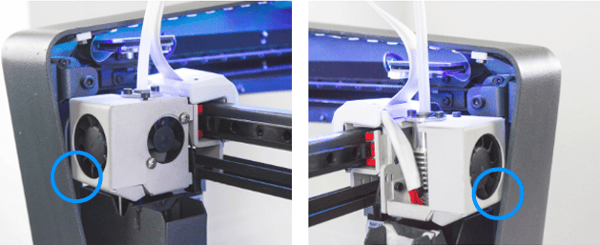

1. Place the printing heads on the sides of the carriage and bring the carriage to the front of the printer, so you can check the distance between the printing head and the printer structure on both sides.

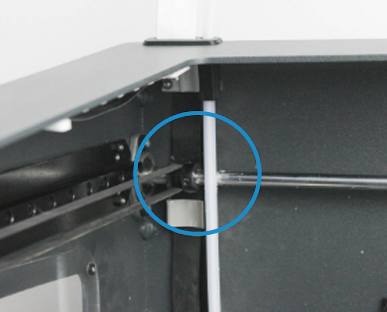

If one of the heads is touching the frame before the other does:

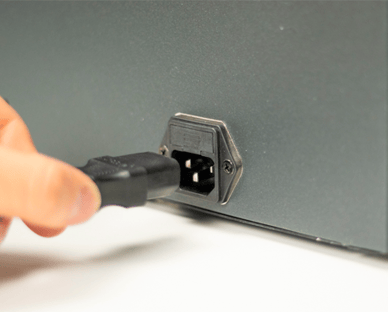

2. turn off and disconnect the printer.

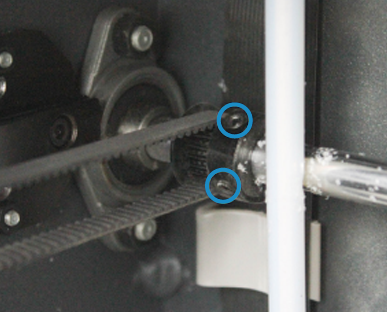

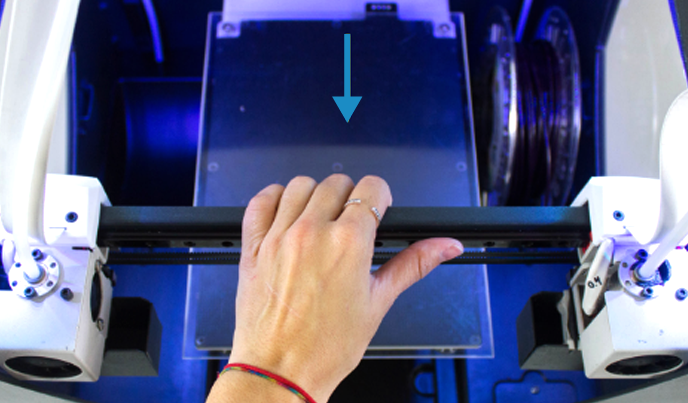

4. Once loosened, position the axis manually towards de front until you see that the two heads touch the machine frame. Hold the position while you retighten the two screws of the pulley.

Note: It could be that the screws were too tight to the pulley because some of the screws have thread glue on them. Don't try to force it, there are other methods to realign the printer's carriage.

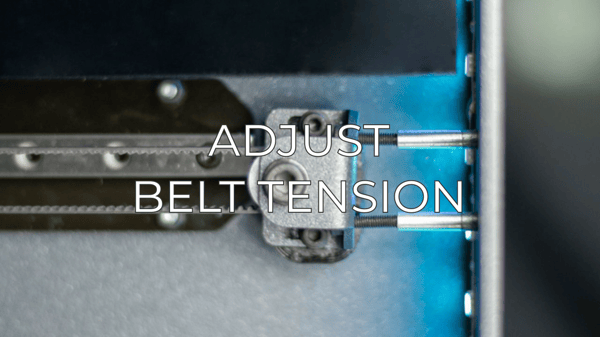

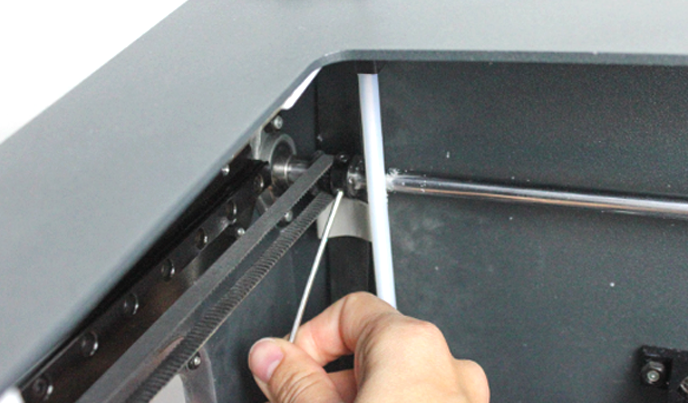

Loose one of the Y belts, press the X-axis gently against the printer frame, and put the belt back again on its place while holding the axis touching the frame.

Check the belt's tension after you remove and install the belts, this article will help you with this: How to adjust the tension of the belts (BCN3D Sigmax)

Conclusions

It's important to check the parallelism when you adjust the Y belts to avoid misalignment in the carriage and damage other components, like the X carriage holder or the Y belts. You can do this every month as a maintenance task.

Forum Community

This article doesn't fix your issue? Check out our forum community for more info about this

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done. Maintenance Plan

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |