How to change the X endstop (BCN3D Sigma)

In this article you will learn the procedure to change the X endstop

| Tools | |

Pliers |

|

Allen key 2.5 mm |

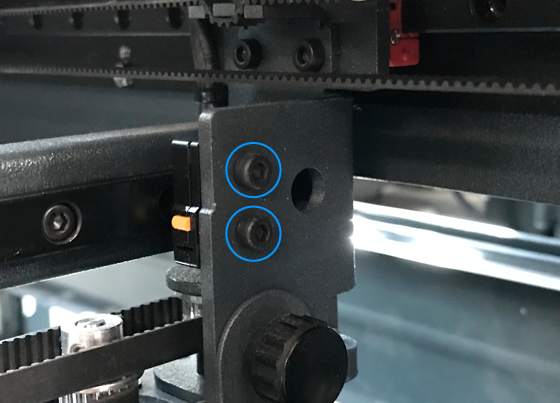

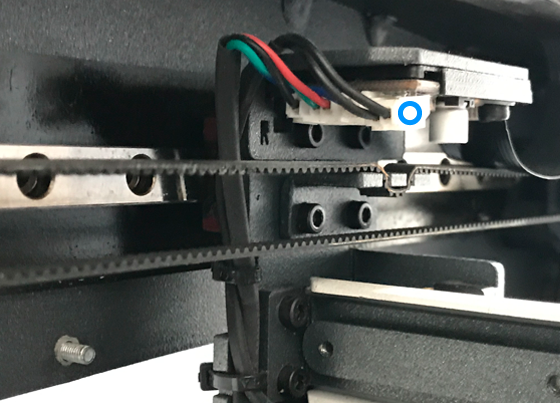

| 1. Loosen the two screws that hold the endstop to the aluminum holder. |

2. After removing the screws, check if your endstop can be disconnected by pulling from the cable connections. Do not use force when pulling from the cables since earlier versions of the endstops come together with the cable.

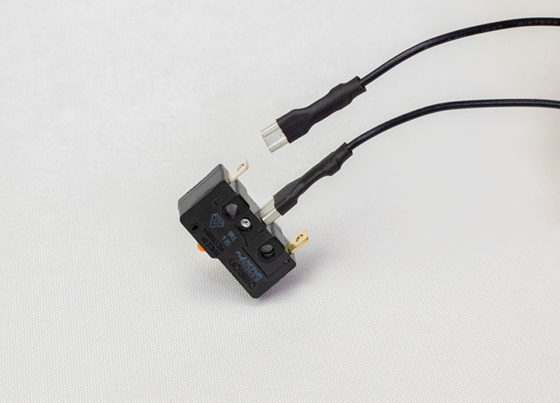

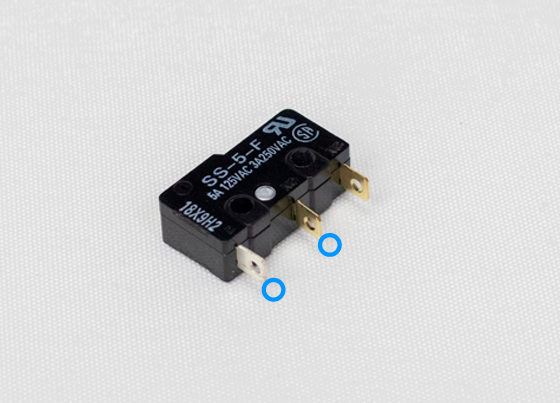

If it gets disconnected, you can connect the new one and screw it in place. The next image shows you the terminals and how you should connect them.

Otherwise, if you have to replace both the endstop and the cable, continue with step 3.

|

|

3. Cut the two tie wraps that hold the endstop cable.

4. Disconnect the endstop from the driver.

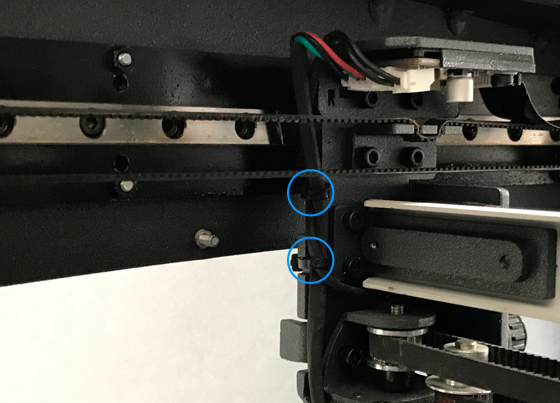

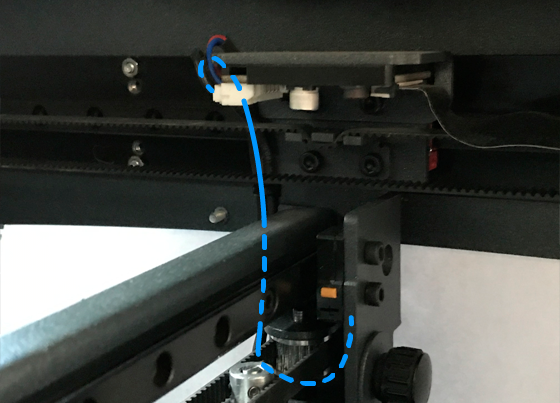

5. Install the new endstop as shown in the picture, the cable has to go under the X guide and the orange switch has to be at the bottom part of the endstop.

Conclusions

Make sure that the endstop cable is immobilized with tie wrappers to avoid it being caught on moving parts of the printer.

Forum community

Repair didn’t go as planned? Check out our forum community for troubleshooting help.

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done. Maintenance Plan

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

| Parts | Buy these parts | |

|

Endstop X |

RELATED ARTICLES |

|

|

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |