In this article, we'll take a deep look at the Fade option in the Mesh Mapping function. An option that will help you achieve the best results depending on your printing needs.

Why the Fade option was born?

Mesh Mapping is a feature that allows you to adapt the printing surface position as a layer is being printed. The print model adherence is improved and the printing procedure satisfaction is secured.

Due to the manufacturing process of the printing surfaces, those ones are not usually perfectly flat. They have small undulations (tenths of a millimeter) that affect either the adherence of the printing model as well as the first layer finish.

Knowing those two things we can already detect an issue. When Mesh Mapping is on, the printed layers will have the same undulations as the printing surface so that all the printed models will have these undulations on their surface.

This may or may not be a serious issue depending on the needs and use of the print. That's why the Fade option was created. A new feature that allows us to select between letting the printer fix those undulations or having a printed model with them.

How does this function work?

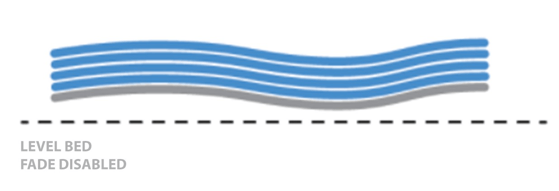

One of the most important things that you have to know when using the Mesh Mapping feature is that when you adjust the height because of the undulations so that the print sticks perfectly to the printing surface, the same relief is reproduced through all the printed model

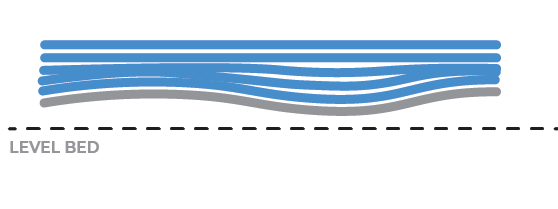

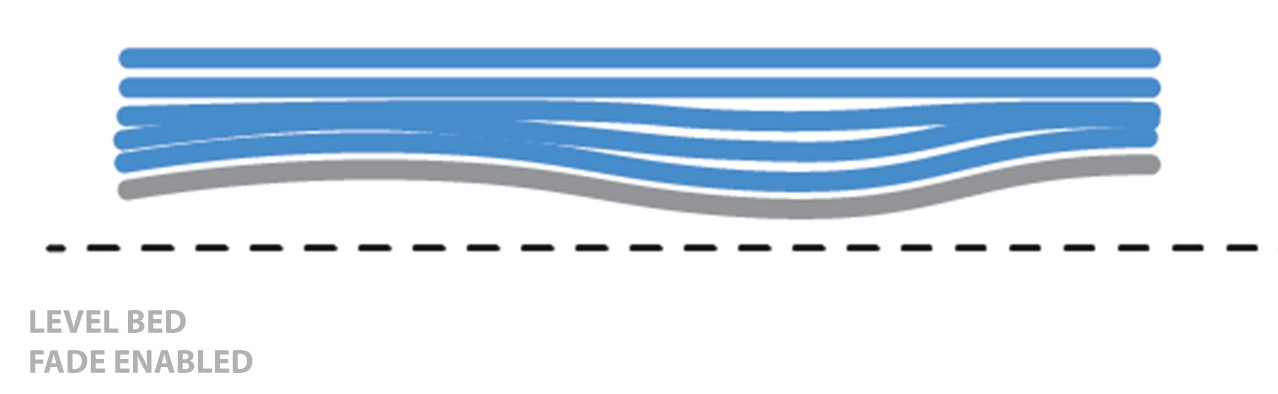

In the next scheme, you can see how the layers adapt to the relief:

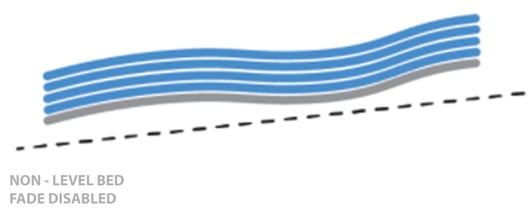

Even when the surface flatness is not perfect, the Mesh Mapping feature achieve as we can see in the next image, transfer this homogenization to the rest of the print.

However, the Z-axis motor reduces its service life due to having to constantly be working on adjusting this height for the surface irregularities.

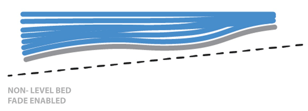

The Fade option's main goal as we've already explained is to compensate the layers so that independently of the printing surface relief or even the flatness and slope of this one, the final print results are flat. Furthermore, this makes the Z-motor service life long as the height adjustments reduce progressively.

When to use Fade?

In BCN3D we usually recommend turning on the Fade feature to prevent Z-motor wear due to the constant height adjustment that it does when this feature is off.

It's interesting to turn it on when you want the upper layers and walls of the model to have the design geometry. But the height between the upper and bottom layer will not be uniform.

However, if you really need the model to have the same height between the bottom and top layers it is best to turn off the fade feature, knowing that both layers will have those printing surface undulations.

.png?width=558&name=Fade-mesh-mapping-01%20Cropped%20(2).png)