When the Epsilon gets stuck in the home position and produces a loud screeching noise, this is a clear sign that you need to check the endstops. There is a possibility that one of them is stuck or broken and needs replacing.

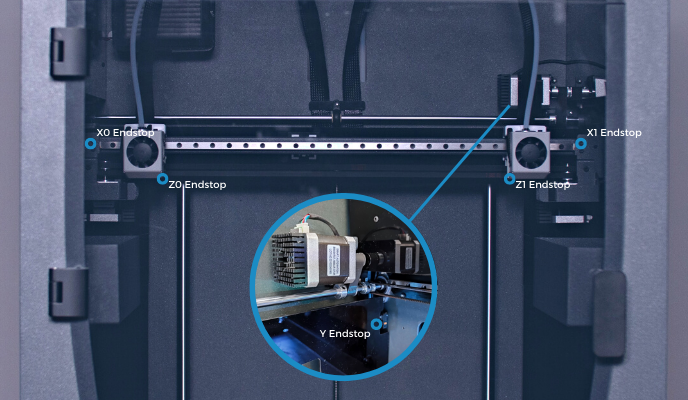

Endstops location

Below you can see where the printer’s endstops are placed:

- Note: you can click on the picture to enlarge it.

It's possible that you need to disassemble the endstops from the printer in order to check them properly. At the end of this article, there are links with instructions that can help you with this process.

The most common endstop related issues

1. Cable connection issues

Check that the endstop cable is properly connected to the driver or extruder board depending on the axis. Also, make sure that the cable is in good shape.

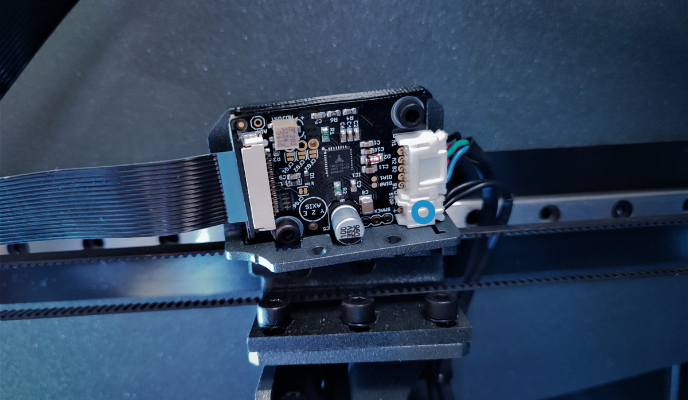

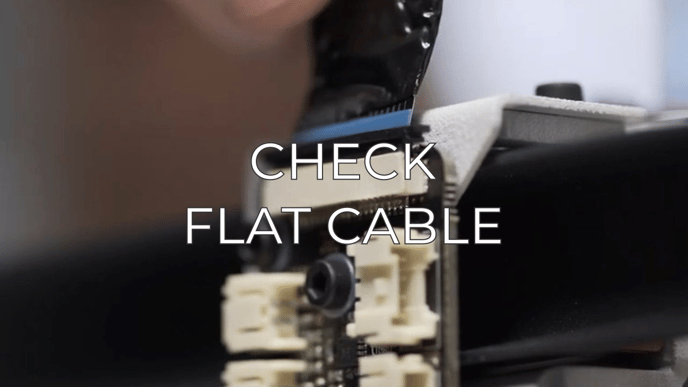

2. Bent flat flexible cable

Usually, it is related to the Z endstops. Check if the hotend flat cable is bent on the extruder board connection. If it is, you can manually straighten it and do a bed calibration to check if the problem continues.

3. Jammed switch.

It can be unblocked using a cutter or a needle. Next, check if the button does click easily. If the block continues, would be necessary to replace the endstop.

4. Broken endstop

Replace the endstop for a new one, see the parts list at the end of the article.

If none of this works, replace the Endstop, you can learn how to do that in the following articles: