The guide of the basic parameters to print 316L stainless steel for industrial applications on FDM printers

What is 316L?

This material can be used to print tooling, functional prototypes, jigs, and fixtures and is suitable for serial production to functional prototypes.

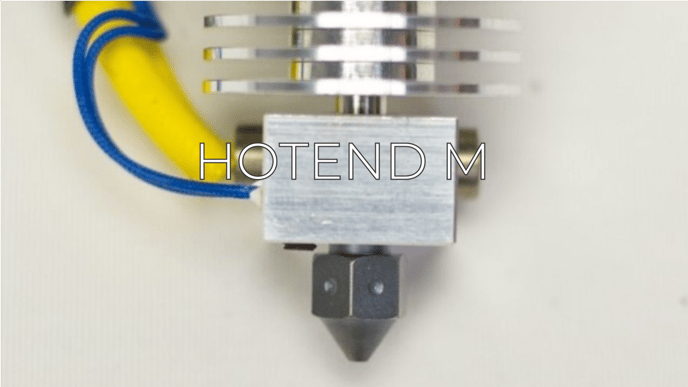

To use 316L filament you must install the Hotend M. Printing 316L and 17-4 PH with a standard nozzle will seriously damage the hotend.

You can purchase 316L from the BASF online store: Ultrafuse 316L

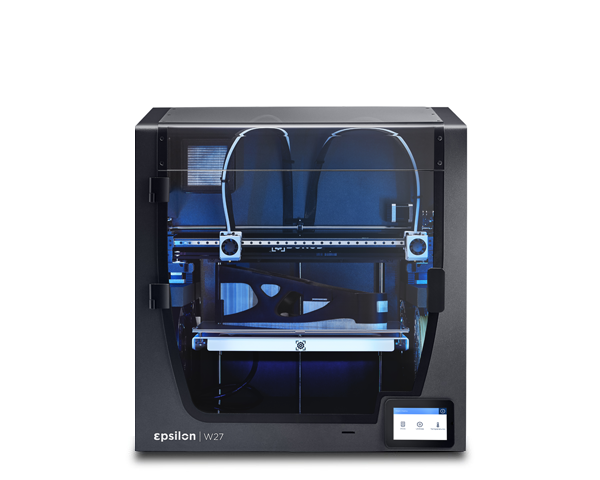

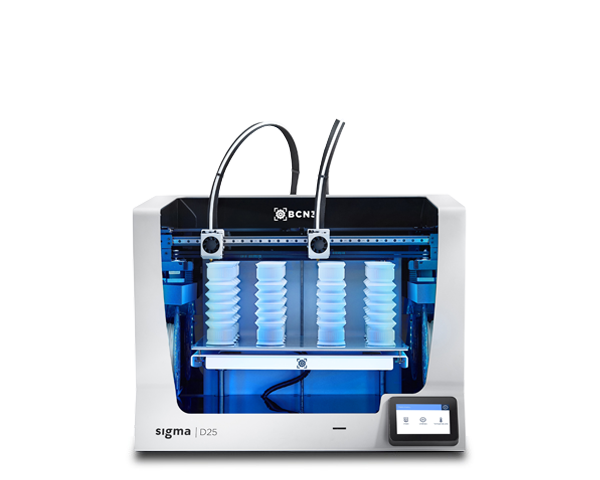

316L compatibility with BCN3D printers / hotends:

Supported materials combinations

The ultrafuse 316L is not compatible with the current BCN3D Filaments.

316L printing settings - Hotend M

- Note: BCN3D Lab develops specific configurations for each material and printer. Make sure to use the last BCN3D Stratos version.

Build plate adhesion

Recommendations

This filament doesn't absorb humidity from the air. However, if the material is not in use for extended periods of time, it is recommended to keep the Ultrafuse 316L spools in a box or airtight container.

Ultrafuse 316L emits low levels of fumes and particles when printed. We recommend printing it in a well-ventilated area to ensure a healthy environment.

Clean the nozzle before and after each print job to ensure a good extrusion and get cleaner prints.

Digital documentation of the 316L

Here you can find and download the Technical data and the Safety data sheets of our 316L:

.png?width=491&name=magigoo-metal%20Cropped%20(1).png)