In this article you will learn some information to help you master 316L

Note: This article contains advanced information related to the Ultrafuse 316L. Our default profile for Ultrafuse 316L has been adjusted to get good quality and optimal results and is fully tested in our lab. These tips complement the settings to ensure the best print quality with 316L.

Ultrafuse 316L is a filament composed of 80% stainless steel powder and 20% polymer content designed to be easily printed with FDM technology. The maximum resistance and hardness of this material are reached after a process of debinding and sintering, allowing the serial production of functional parts at a very low cost.

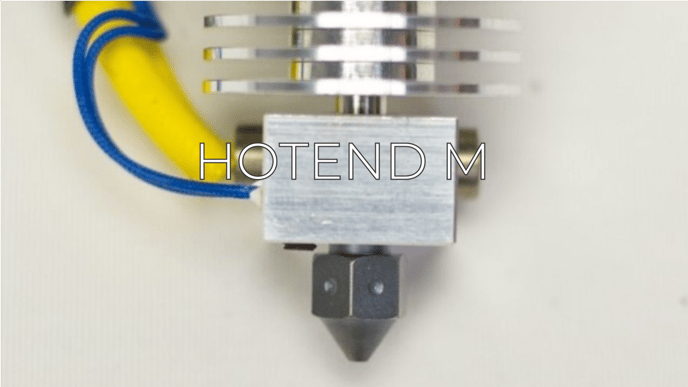

An abrasive material

Ultrafuse 316L contains steel particles and is quite abrasive. It is recommended to print it with the BCN3D Hotend M. Otherwise, it will wear out the standard hotends, making them unusable in a short period of time.

Check this article if you are interested in knowing more about the reasons why you must print this filament with our Hotend M:

First layer adhesion

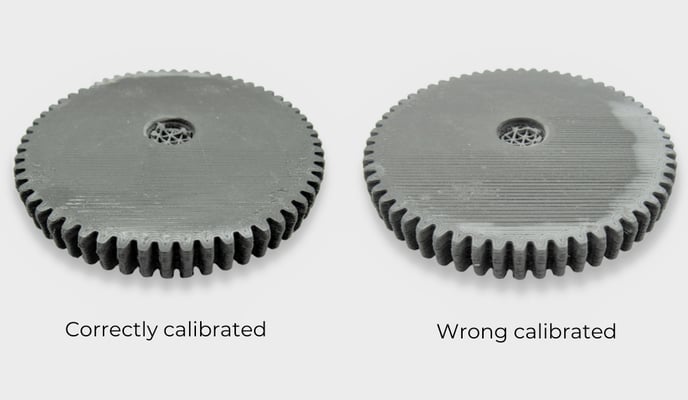

It is very important to print the first layer correctly to avoid deformations in the model after the debinding and sintering process. A first layer that is not well stuck or is excessively stuck to the platform will cause the deformation of the piece.

We recommend you do a check during the printing of the first layer, to make sure that it is sticking properly to the printing surface.

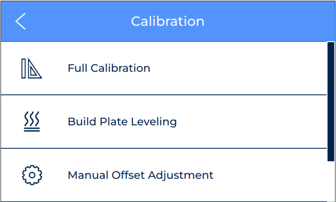

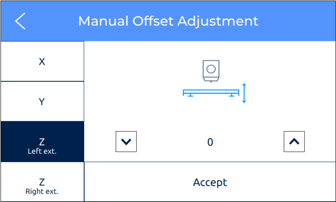

If you need to update a Z offset adjustment, you can go to the screen menu calibration / manual calibration and decrease or increase the distance between the hotend and the printing surface.

We recommend enabling the build plate adhesion type to Skirt. You will find this parameter in the Build Plate Adhesion of our slicer BCN3D Stratos

Note: You will find more information about the calibration process in this article: Hotends calibration (Epsilon Series)

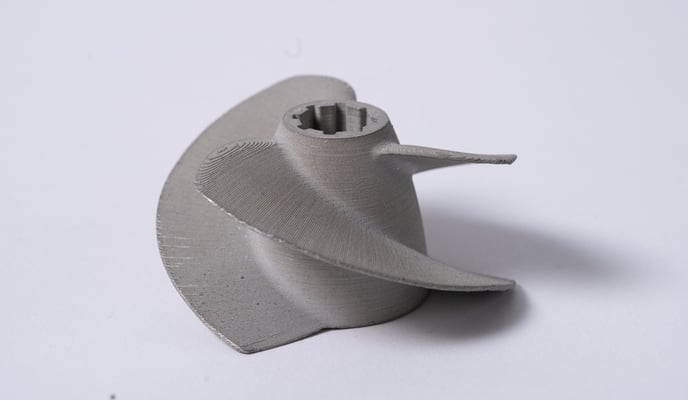

Scaling the piece

After the debinding and sintering process, the printed part shrinks. With the recommended printing profile of BCN3D Stratos, it is needed to scale the piece 119% in the direction of the X and Y axes and 124% in the Z-axis, to ensure that the piece has the right measurements.

%20Cropped.png?width=688&name=35%20(3)%20Cropped.png)

Note: To ensure that the debinding and sintering process is performed correctly, the dimensions of the piece cannot be larger than 100*100*100mm.

The most accurate results obtained are the pieces that have a 60*60*60mm dimension.

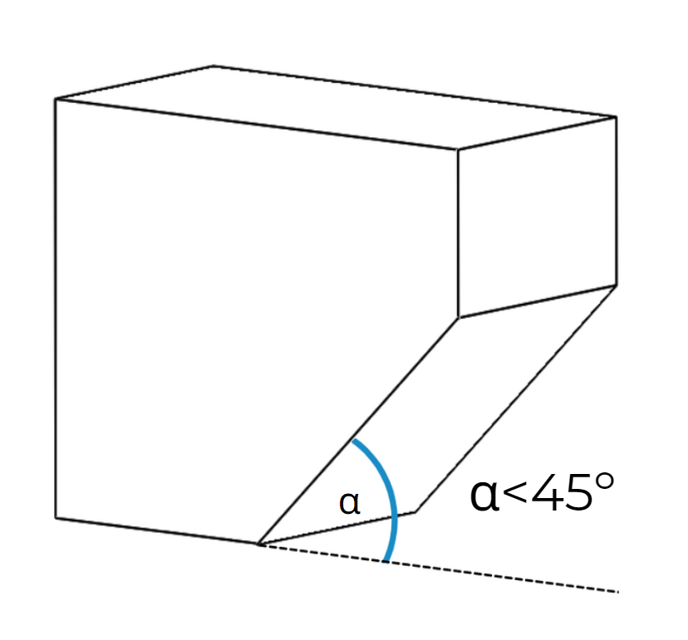

Setting the supports

This is a material that requires a large amount of support due to the thermal processes to which the pieces are subjected to make them functional.

Furthermore, you must increase the support density to guarantee the stability of the piece between 30 and 40%.

Let the piece cool down after the print.

The Ultrafuse 316L is a material that must slowly cool down to avoid piece deformations during the sintering process because the brusque temperature changes generate tensions that can break the piece.

Suggestion: Leave the piece inside the printer at least 10 minutes after the print.

Remove the piece carefully

The printed parts are quite fragile before being sintered, so it is necessary to tread them carefully and to remove the parts delicately. Once the printing surface has completely cooled down, put some water above the piece and wait until the sticker dissolves.

To remove the piece you can use a spatula and follow the steps in this article: How to safely remove prints

Suggestion: In the case that the base of the piece is not perfectly flat, you can sand the surface to improve the flatness before the sintering.

Postprocessing the Ultrafuse 316L

Once the piece is debinded and sintered, it can be post-processed like any other metal piece, it can therefore be subjected to cutting, welding, and polishing processes.

These processes are explained in this article: Post-processing metal parts.

Forum community

Need more help? Check out our forum community for troubleshooting help.

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done. Maintenance Plan

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |