In this article you will understand the importance of using the hotend M to print metal materials.

The hotend M is only compatible with the BCN3D Epsilon and it is the suitable hotend to print with metal materials such as the Ultrafuse 316L and the Ultrafuse 17-4PH.

The metal filaments are highly abrasive so if they were printed through a brass standard hotend, they will wear away quickly. To solve this issue we have designed the hotend M, a hotend with a hardened steel nozzle. This article provides all the information you need to know about this device.

Why must I print with the hotend M?

To understand why using this hotend is necessary during the printing of metal material we must talk about the hardness.

Filaments like the Ultrafuse 316L and the Ultrafuse 17-4PH contain steel particles that scratch the nozzle's surface. Steel is a material harder than brass (the material that the standard hotends are made of), so it damages the nozzle by increasing the hotend diameter.

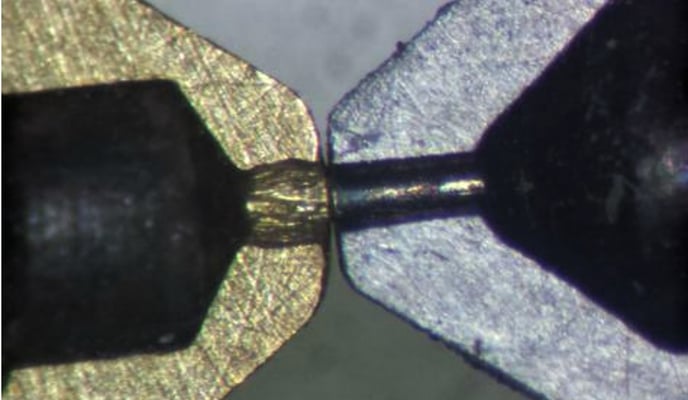

In the following image you can see the short term effects of printing metal filaments with a standard hotend:

As you can see, the brass nozzle diameter has increased and it has been deformed internally. This damage in the nozzle causes a poor filament extrusion and increases the chances that the filament clogs the hotend.

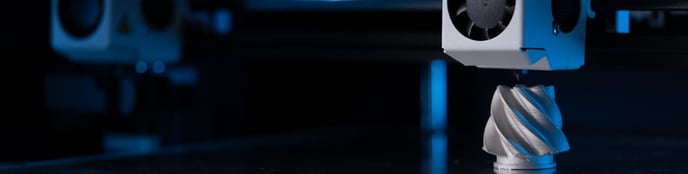

What makes the hotend M special?

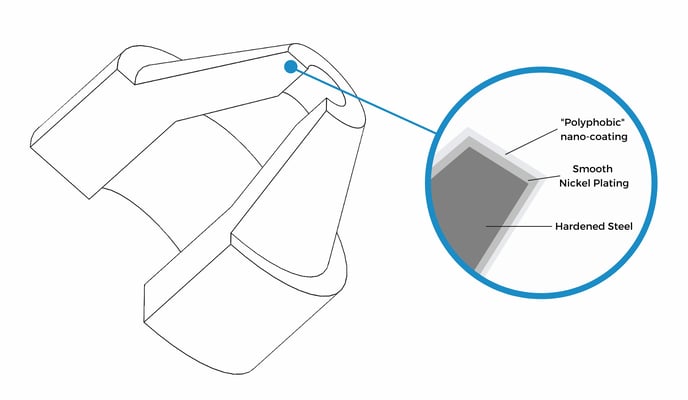

The hotend M nozzle is composed of hardened steel with a nickel cover and a "Polyphobic"nano-coating, which makes the hotend harder and reduces the friction between the filament and the nozzle.

- Less material accumulation, from sticky and fiber material at the end of the nozzle.

- A more reliable first layer; the slippery coating tends to drag the material specifically in corners where the layers can detach.

- Solid and flat top layers, with a shiny finish as a result of the soft placement of material.

- Easier nozzle cleaning, the small amount of material that sticks to it can be cleaned easily with a piece of paper leaving a very clean nozzle.

In addition, the hotend M has an intern covering that allows that the filament slides without any problems.

Can I use the hotend M with non-metal materials?

The short answer is that it is not recommended, here are the reasons:

For its design the hotend M is delicate, the intern covering wears away when changing filaments or cleaning the hotend, so it reduces its life span and can cause the hotend to clog.

The heat transfer is different between the hotend M and the other hotends, so the hotend M is ideal for metal materials, the hotend X for fiber-filled materials, and the standard hotends for materials without fiber.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |