Table of Contents:

Support extruder

Support Extruder

Using this parameter you can choose which extruder prints the support material and also the parts of the structure that will be printed. This parameter is divided into the following options:

Support infill extruder

First layer support extruder

Support interface extruder

Support roof extruder

Support floor extruder

Support placement

This option allows you to indicate where the supports will be generated and contains the following options:

Touching the printing surface: the support material is only printed on the printing surface.

Everywhere: supports are generated under all areas of the model that require support.

Recommendations:

Materials

PVA | BVOH As they are soluble materials, the supports can be printed everywhere.

Support overhang angle

the minimum angle where all overhangs will have supports.

- 0º will make all the overhangs have support

- 90º will not generate any supports

Recommendations:

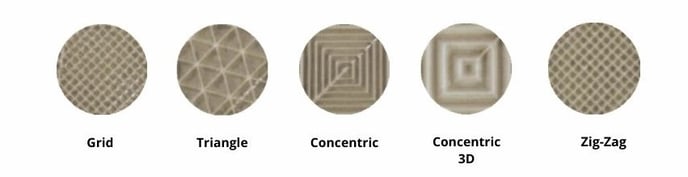

Support pattern

There are different patterns for printing supports. Patterns influence the quality of the support, making it stronger or easier to remove.

Recommended patterns:

Grid: indicated for water-soluble materials such as PVA and BVOH. It creates highly resistant structures that are easy to dissolve.

Zig Zag: recommended for non-water soluble materials. The structure is not very resistant but very easy to remove, leaving minimal detail on the contact surface.

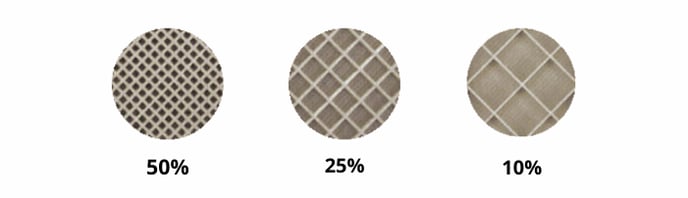

Support density

the amount of material used to fill the supporting structures. Higher density means stronger supports but also more difficulty in removing the piece.

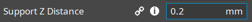

Support Z Distance

%20Cropped2.jpg?width=688&height=175&name=Image%20(3)%20Cropped2.jpg)

With this parameter, you can configure the distance between the supports and the model along the Z-axis. It is divided into two options:

Top distance: the distance between the top of the support and the piece.

Bottom distance: the distance between the bottom of the support and the piece.

Distance support in X/Y

Allows you to adjust the space between the supports and the piece in the X and Y directions. Increasing this value prevents the support structure from mixing with the walls that do not require support.

Forum community

Need more tips? Check out our forum community for help.

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done.

Maintenance Plan (Epsilon Series)

Maintenance Plan (Sigma Series)

Maintenance Plan (BCN3D Sigmax)

Maintenance Plan (BCN3D Sigma)

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |