How to adjust the Z axis lead screw nut (BCN3D Sigma)

| Tools | |

Allen key 2.5mm |

If when trying to raise the printing platform, it stays at its bottom position and makes a loud noise, probably the cause is that the lead screw nut is misaligned with the printing surface. In order to solve this follow these steps:

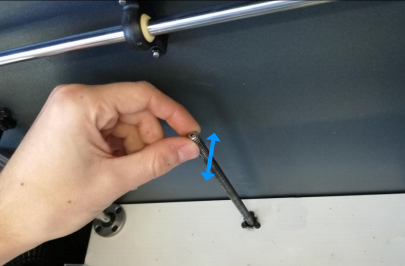

| 1. Loosen the three screws placed around the Z-axis lead screw. |

2. Move back and forth the lead screw to correct its position before tightening the screws again. This correction should be minimal, just enough to align the screw in a natural position.

Note: If you can't tighten the screws, try to spin a little the lead screw to align the holes of the nut with the holes of the printing platform.

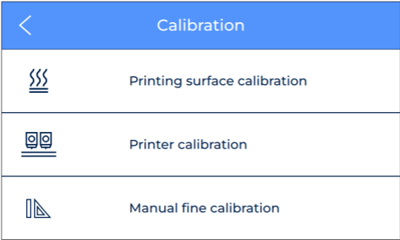

3. Go to Utilities/Calibration/Printing surface calibration and follow the steps. Verify if the printer can now raise the platform. It's possible that you have to repeat this process to get it perfectly aligned.

Conclusions

If you can't move the printer surface after following these guidelines, please check the flat cables connections, check out this article: How to check flat cable connections (BCN3D Sigma)

If the printing surface still doesn't move after checking the flat cables, please contact with the BCN3D support team by filling this form.

Forum community

Repair didn’t go as planned? Check out our forum community for troubleshooting help.

It's important to keep your printer in good shape to make the most out of it. In this chart you can find a list of the extruder maintenance procedures and how frequently these should be done. Maintenance Plan

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

RELATED ARTICLES |

|

|

|

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |