It is recommended to weekly perform a printing surface calibration and regularly clean the surface.

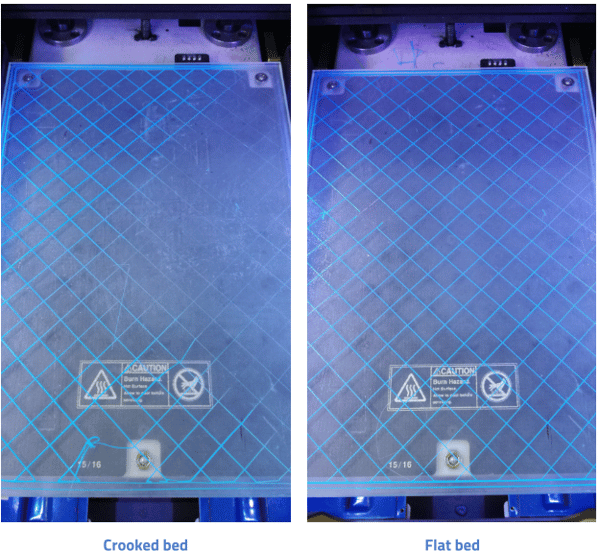

Proper calibration and therefore good printing quality depend on the flatness of the printing surface. However, sometimes it is necessary to run a deeper calibration and correct the calibration offsets. Follow the next steps to know how.

1. Run a Printer Calibration and recalibrate the Z axis in both heads.

2. Print the Mesh file to check the printing surface flatness: *Sigmax file meshX.gcode

3. If the printing surface isn't perfectly flat, try to manually adjust the back screw nut and the front thumbscrews of your platform. You can use an 8mm Socket Driver on the backside screw.

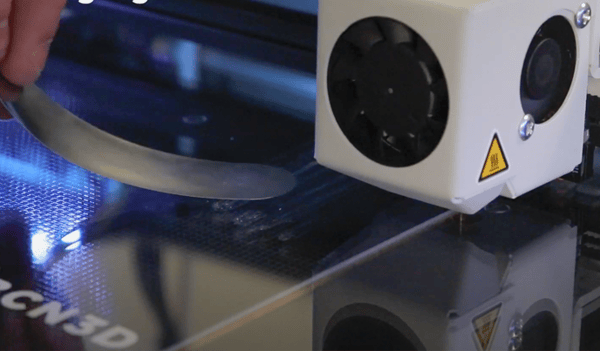

Move the hotend and place the nozzle over the printing surface, using it as a reference. Print again the mesh.gcode file and verify the surface flatness.

Once you get a good result, follow these steps:

3.1. Connect the printer to your computer using the USB cable.

Tip: If your computer USB port can't detect the printer, follow this article:

3.2. Download, install and configure Pronterface on your computer following the instructions on this link: Pronterface.

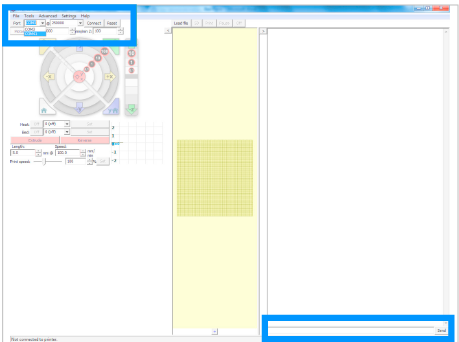

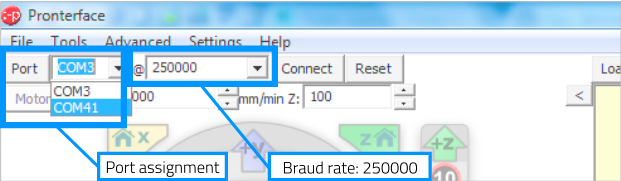

3.3. Open Pronterface and set the USB port and the baud rate speed. The baud rate will be 250000.

3.4. Then click on Connect, you will be able to check if it's connected on the console log (right side screen).

3.5. Run a bed calibration and load the DZ2 and DZ3 values as explained here: Bed calibration offsets procedure.

3.6. Run a Printing surface Calibration, then print again the mesh.goce file to check if new results are better and your printer surface is flat.

Conclusions

Hereinafter, it is not necessary to do this process with each printer calibration, the new parameters are loaded on the mainboard.

Is recommended to correct the calibration values if you use differents printing surface plates for the same printer. Everytime you change from one to the other.

You can monthly follow the steps described in this guide, as a maintenance process of your printer.

This article doesn't fix your issue? Check out our forum community for more info about this

It's important to keep your printer in good shape to make the most out of it. In this chart you can find a list of the extruder maintenance procedures and how frequently these should be done. Maintenance Plan

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |