How to print with BCN3D PP

Is the most common polymer in the industry and house applications thanks to its chemical resistance, flexibility, and durability. It's light and its good interlayer adhesion allows it to print water-tight containers.

What is the PP?

|

PP (Polypropylene) is a semicrystalline thermoplastic known for its resistance to chemical agents. It is completely inert and does not easily interact with any substance. For this reason, it is commonly used for the packaging of food and chemicals. It is a flexible and durable material, with a high resistance to impacts and wear. |

This material is ideal for applications where is necessary light components, resistant to moisture and abrasion.

You can purchase PP from our store: BCN3D PP

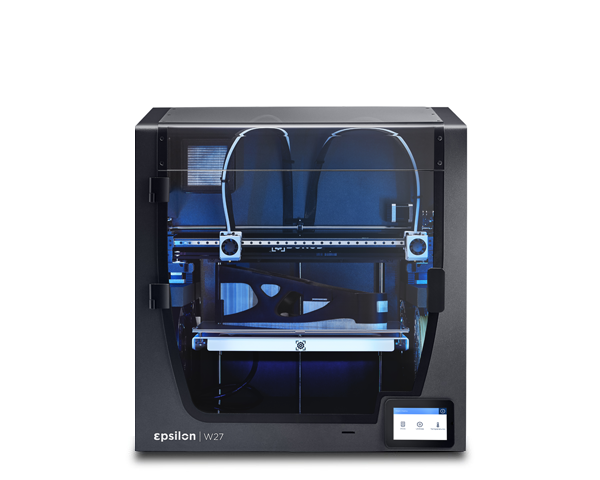

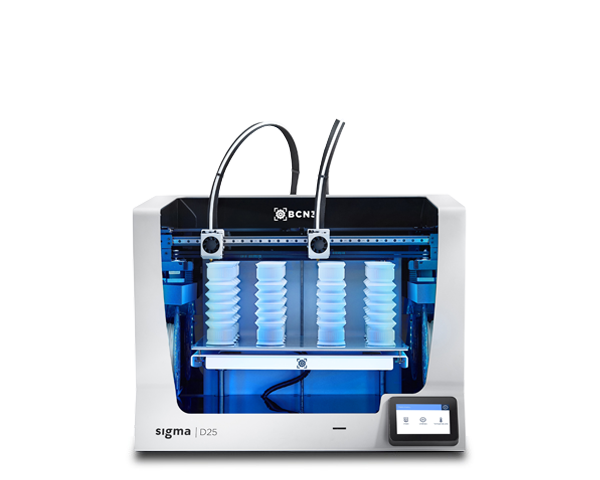

PP compatibility with BCN3D printers / hotends

| ✔ | ✔ | ✗ | ✔ | ✔ |

|

|

|

|

|

| 0.4 / 0.6 / 0.8 / 1.0 | 0.4 / 0.6 / 0.8 / 1.0 | 0.4 / 0.6 / 0.8 / 1.0 | 0.4 / 0.6 / 0.8 /1.0 |

Supported materials combinations

The BCN3D PP is not compatible with the current BCN3D Filaments.

| Standard materials |

||||||||||||||

| PLA ✗ | TPU ✗ | PVA ✗ | BVOH ✗ | TPLA ✗ | PET-G ✗ | |||||||||

| Technical materials |

||||||||||||||

| ABS ✗ | PA ✗ | PP ✔ | ||||||||||||

| Composite materials |

||||||||||||||

| PAHT CF15 ✗ | PP GF30 ✗ | PET CF15 ✗ | 316L ✗ | 17-4 PH ✗ | ||||||||||

PP printing settings - 0.4 mm nozzle

| Extruder temperature | 210ºC-240ºC |

| Build plate temperature | 70ºC |

| Speed | 40-80mm/s |

| Retraction speed | 40 mm/s Full enclosure models 35 mm/s Open models |

| Retraction distance | 4 mm Full enclosure models 5 mm Open models |

| Cooling fan | 100% |

| Minimum layer height | 0.15-0.4 mm |

- Note: BCN3D Lab develops specific configurations for each material and printer. Be sure to use the latest BCN3D Stratos version.

Build plate adhesion

|

Magigoo PRO PP is designed for professional use, to work exclusively with polypropylene filaments. The part should be relatively easy to remove once it cools and the glue residue should also be easily cleaned off if the included procedure is followed. It is best to apply Magigoo when the printing bed is cool. To reduce the warping is recommended to preheat the hotbed for 5 minutes before print. |

|

Recommendations

Plastics absorb moisture from the air. If the material is not in use for extended periods of time, it is recommended to keep the PP spools in a box or airtight container with desiccant to keep them dry.

PP emits low levels of gasses and particles when printed. We recommend printing it in a well-ventilated area to ensure a healthy environment.

Digital documentation of the PAHT CF15

Here you can find and download the Technical data and the Safety data sheets of our PAHT CF15:

|

|

|

| Send us your comments about this article |

|

||

RELATED ARTICLES |

|||

|

|

||