The safety guide will show you all you need to know to use your printer safely

Contents:

Where to install the BCN3D Sigmax

Safety precautions when moving the BCN3D Sigmax

General information

To avoid potential risks the user should read and understand the following safety measures (you are strongly advised to read this before using the 3D printer).

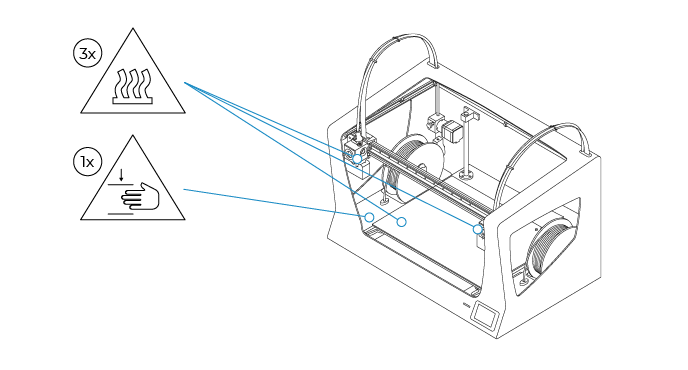

There are areas where extra care should be taken, safety alert stickers have been affixed to the relevant parts of the machine to warn the user of potential hazards.

Legal notice:

BCN3D is exempt from any liability if the user does not follow the use and safety instructions.

Hazards

The following stickers have been affixed to the printer to warn users about the hazardous areas of the machine, and actions that are not recommended as they will stop the machine from working properly.

- Supervise the printer while it is printing to make sure it is working properly.

- The spatula can be a dangerous tool that may cause injuries. Use it only to remove plastic residue after a calibration assistant or a printing job.

- Handle the printing surface with care. Make sure it is not dropped or hit with anything as this could seriously damage it.

Tip: Check this article about how to safely remove prints: How to safely remove prints

The printer is powered by mains voltage, which is hazardous when touched.

Always connect the BCN3D Sigmax to an electrical outlet according to the current legislation to prevent any electrical risk.

If you need to do any maintenance or modifications to the BCN3D Sigmax, it's very important to turn off and disconnect the printer to avoid short circuits over the electronics or any risk of electrocution.

Even if the printer is turned off, you will need to disconnect it from the power supply to perform changes in the inner components.

In the case of an emergency, stop the machine immediately by pressing the switch, and disconnecting the power supply. This will prevent more damage to the printer. Check visually the printer and get in contact with the BCN3D support team by filling this form.

Warning! As with any other appliance, do not touch the terminals of the mains, the switch, or the power supply. There is a risk of electrocution.

Do not touch the hot parts (heated bed and hotends) there is a potential risk of burns: the hotend can reach temperatures up to 290°C, while the heated bed can reach peak temperatures of 150°C.

When the printer ends the print job, wait 15 minutes before touching the printing surface, the heated bed, or the hotends.

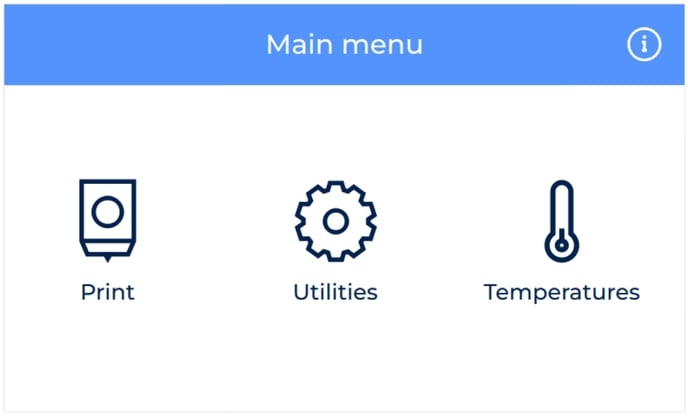

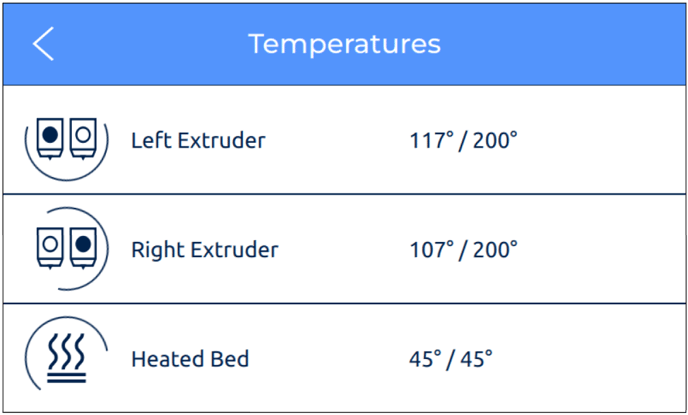

Pay attention to the temperatures screen to know when the hotends or the heated bed are too hot to touch them.

If you need to remove the printing surface when this and the hotends are hot, stop any process, make sure that the printing heads are over the purge tanks, and use heatproof gloves to remove the printing surface.

Do not put any object or part of the body between the moving parts of the printer, when it is moving or can start moving. Check that the moving parts are free of any obstacle before starting to work with the printer, to avoid damage to the motors, linear bearings, and rails.

If you need to move up the build plate, do not force its movement, it can damage the printing platform and the mechanical parts of the BCN3D Sigmax.

If the printer does a movement that results in a crash, turn off the printer and check if any component is damaged. Usually, these problems are caused by an endstop malfunction. You can try to change the endstop or check if the flat cable is connected properly, check these guides to get more information about this:

How to check the flat cable connections (BCN3D Sigmax)

How to change the Z endstop (BCN3D Sigmax)

Some printing materials are not innocuous and emit toxic fumes. It's recommended to always print in large, well-ventilated spaces, use a protective mask, and do not breathe closer than 25 cm from the tool head when printing.

Where to install the BCN3D Sigmax.

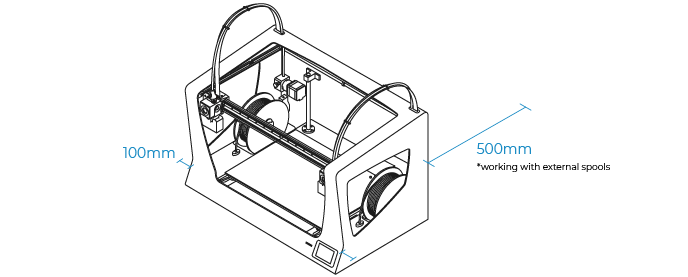

In order to ensure easy access to the printer during maintenance tasks or its normal use, install the BCN3D Sigmax with enough space between walls and other equipment.

The 3D printer will need a clearance of 100mm at the sides to get easier access to the power button.

If you want to work with external spools it's recommended to provide a 500mm clearance at the back of the printer.

Install the printer on top of a solid table or workbench able to support at least 30kg and that has at least 20% more surface than the footprint of the printer in each direction.

Use the BCN3D Sigmax in an environment from 15 to 30ºC and relative humidity below 50% to avoid printing issues or damage to the electronics of the printer.

Safety precautions when moving the machine

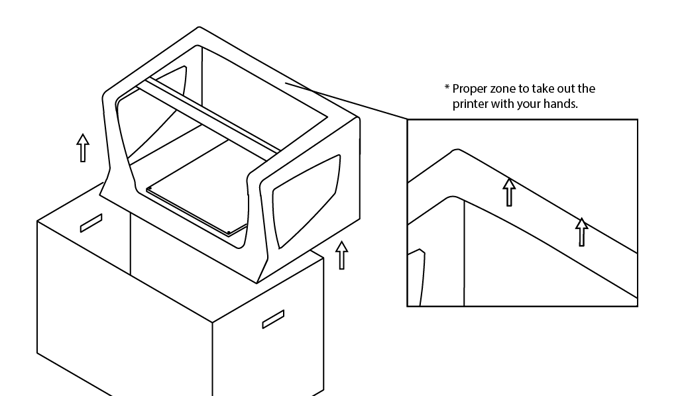

To ensure the safe movement of the machine, follow the steps described below:

Warning! The printer is heavy, two people are necessary to perform this step. Make sure that the table where the printer is being installed is close enough.

1. Turn off and disconnect the BCN3D Sigmax.

2. Remove the printing surface before moving the machine.

3. Grab it from the upper arches with a partner, pick it up by carrying the weight from your legs, not your back, to prevent injuries.

Warning! Be extra careful when putting the printer on its new location, make sure it is stable in place and no limbs are underneath before putting it down.

Conclusions

If you need more help about how to use the printer, check our user guide: User guide (BCN3D Sigmax)

Need more tips? Check out our forum community for more info about this

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done. Maintenance Plan

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |