Apply these simple tips about the retractions and get clean prints

Why does the filament wear out with retractions?

During the printing process, the gears of the extrusion motors gently "bite" the filament to move it forward or backward. If an area of the filament is repeatedly marked by the extrusion motors, there may come a point where the section of the filament is reduced so much that the motors cannot pull it.

This effect is known in English as "Filament Grinding" and is a common cause of under extrusion in parts that require many retractions.

To avoid wear of the material, there are two possible solutions at the configuration level:

Solution 1. Make use of the Prevent filament grinding parameter

It is the fastest and simplest solution but it consumes a high amount of material, it consists of carrying out a purge of material when many retractions are made in a length of filament.

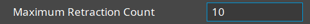

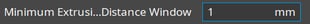

This is done by making use of three parameters: prevent filament grinding, the maximum retract count, and the minimum extrusion distance window.

%20Cropped%20(1).png?width=688&name=Ventana%20de%20distancia%20m%C3%ADnima%20de%20extrusi%C3%B3n%20(2)%20Cropped%20(1).png)

To make use of this solution you must configure the following parameters as shown below:

1. Enable the Prevent filament grinding option.

This option is found in the Materials section. If you can't find it, go to the adjustment menu, parameter visibility adjustment, and select all.

2. Indicates the maximum count of retractions.

To simplify the process, you can use this table as a general rule depending on the type of filament:

| Soluble Filaments | Non-Soluble Filaments |

| 10 retractions | 20 retractions |

3. Set the minimum extrusion distance window to 1mm.

With these values, the printer will bleed material every time 10 or 20 retractions are made in 1mm of filament, which are the average retractions needed to wear out the filament.

Solution 2. Optimize the print profile

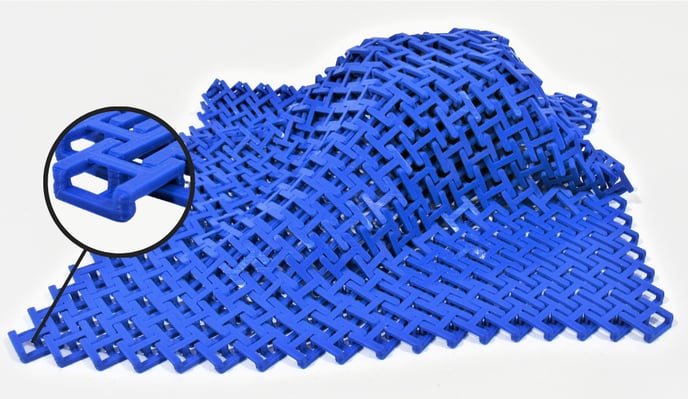

Printing problems are commonly caused by a profile that is not optimal for printing a certain piece, because "it is not the same to print a 40*40*40mm cube as the Sagrada Familia at 1:480 scale".

In addition, improving the printing profile allows the reduction of the cost of material unlike the previous solution. Imagine how much material you could waste on a print like the one below!

to help you with this complex task, you can follow the tips below.

Tip 1. Print slowly

The retractions are related to the printing speed. If you print very fast they will be done quickly which tends to damage the filament.

Depending on the type of material and starting point, we recommend printing at the following speeds:

| Hotend | PLA |

PET, ABS, PA or PP |

Flexible Material | Soluble Material | Material with Fiber |

| 0.4 / 0.6 mm | 30 mm/s | 25 mm/s | 15 mm/s | 20 mm/s | - |

| 0.8 / 1 mm | 40 mm/s | 30 mm/s | 20 mm/s | 20 mm/s | - |

| Hotend X | - | - | - | - | 15 mm/s |

- Tip: In order not to increase the printing time due to the speed reduction, you can adjust certain printing parameters that will allow you to speed up your prints.

-

You can vary the print speed in increments of ± 5mm/s to find the ideal speed to print your project.

Tip 2. Adjust the speed of retraction

Retraction speed not only influences how fast the extrusion motor pulls and pushes the filament, but also the grip between the motor and the filament.

To improve motor grip, it is necessary to reduce the retraction speed. With this, the retraction will be more controlled and the filament will suffer less wear.

Use the values in the table below as a basis for improving the print profile:

| Speed of Retraction | Retract Priming Speed |

| 20mm/s | 15mm/s |

- Note: by reducing the retraction speed, filament remains may remain in the piece and to avoid this you can increase the speed in intervals of 2mm/s.

Retract the filament only as much as necessary

The retraction distance does little to prevent filament wear, however it is a useful parameter to save printing time after reducing the retraction speed.

For retraction speeds between 20mm/s and 15mm/s, the retraction distance can generally be set to 4mm.

- Note: In case of traces of filament or stringing in the piece, you can increase the retraction distance in 1mm intervals.

- It is important not to exceed 7mm to avoid jamming or underextrusion.

Conclusions

- Prevent filament grinding is an easy way to configure and make an effective solution to avoid under extrusion problems, but it requires a high material expense.

- Improving the print profile helps save material.

- To optimize a print profile for parts with many retractions, it is necessary to reduce the print speed and the retraction speed.

- Excessively reducing the retract speed and distance can cause the appearance of stringing in the piece. To solve this, increase the retract speed in intervals of 2mm/s and the retraction distance by 1mm.