You are in a rush, you have tight deadlines and you need your prints to come out fast, no matter what. There are basically five main features you can set up in BCN3D Stratos in order to save time

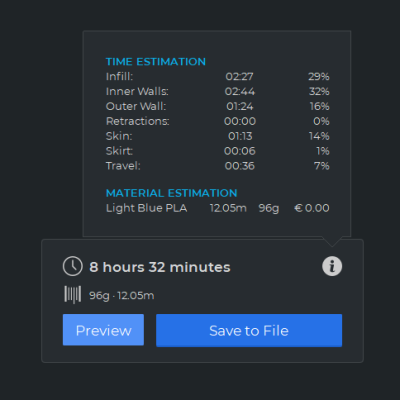

- Tip: You can see where the printer spends more time on by hovering over the print time.

Table of contents

Printing Speed

The first thing that comes in mind is to increase the actual printing speed. This normally is a bad idea, but if we study a bit how the speeds are set up in the default configurations, we can actually save a lot of time.

You can't just crank up the speed and expect the printing time to get super low. You'll rather make the printer noisier and issues like layer shifting will be more likely to happen.

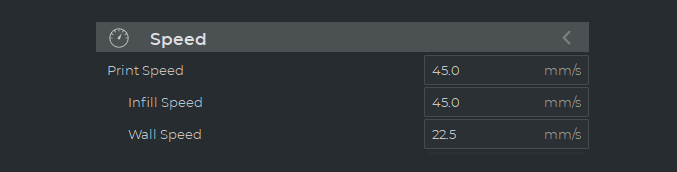

So, how to actually save time by tuning the printing speed? The answer is simple: The speed that you set up in the first stage is actually the infill speed, you just need to speed up the rest of them.

- Note: In BCN3D Stratos, go to Settings/Configure setting visibility and then click on Check All, to see and edit all the printing settings.

The part where the printer spends more time on printing is actually the walls of the print, and those are printed much slower than the actual Printing Speed:

If you increase the Wall and Top/Bottom Speed, as long as it is under 50mm/s, it should be safe for the printer and the part itself, while the printing time would be almost cut in half, depending on the model you want to print.

- Note: the surface quality will be a bit lower than with slower wall speeds, but still it should come out good.

Infill Type and Percentages

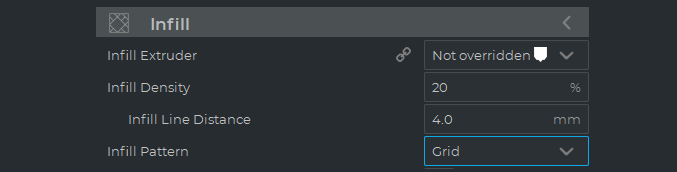

In BCN3D Stratos there's a wide variety of infill types and their density can be tuned at the percentage you may need. If you want strong prints, bear in mind that the print's going to come out slower. If you need them fast, lower the infill percentage up to 10% and change it to a different type to optimize its strength (For example, Gyroid).

- If the printed part doesn't need to resist any mechanical effort, you can set up the gradual infill steps to save material and time.

Hotend Size

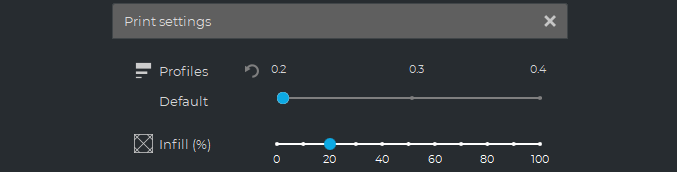

Changing the hotend for another one with a bigger nozzle can also be helpful in reducing printing times. For example, 0.8mm nozzles will print much quicker than 0.4mm ones, as they are capable of extruding more filament at the same time. This can also affect the details of the part. A larger hotend won't print sharp corners or small details.

Layer Height

Layer height is the more determining factor in printing times and it is mostly proportional: If you set a layer height of, for example, 0.2mm, it will come out in half the printing time in comparison to a 0.1mm layer height.

One thing to take into account is that you can't set up a layer height larger than 0.7 times the nozzle diameter. Furthermore, the larger the layer height, the higher the temperature that will be needed in order to print properly.

Speeding up Dual Extrusion Prints

When using the dual extrusion functionality, times are going to get way higher than usual. Tool changes, purging, and added travels are the factors that slow down the prints.

If you want to print in dual extrusion and save time, there are two main features you can tune in order to do so:

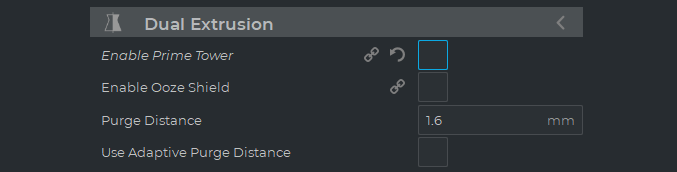

1. Disabling the Prime Tower

The prime tower is a discardable print that is generated in order to deposit all the material that needs to be purged on it to achieve cleaner prints. This tower takes an additional time to be printed and also consumes a bit of extra filament that will be discarded. If you want to get rid of it and still play it safe in terms of quality, disable the prime tower and increase the purge distance a bit to compensate.

- Note: Remember that if you increase the purge distance and you are printing with a Sigma/Sigmax, it's more likely that you have to empty the purge buckets mid-print.

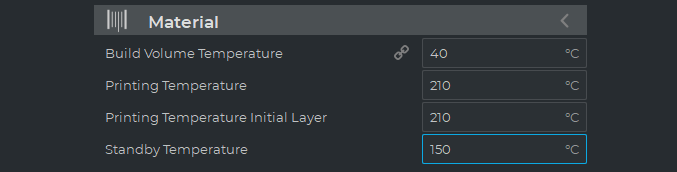

2. Reducing time in Tool Changes

Switching extruders can also take a long time, as they need to heat up from their standby temperature and purge some filament before the printhead actually goes back printing. The best option here is to look at the Standby Temperature of the material. If that temperature is higher, it will take less for the hotend to heat up. You can find this setting in the Material menu.

- Warning! Every material reacts differently when exposed to a sustained temperature for a long period of time. Be extremely cautious when setting this up. 25ºC more will be good for almost every material.

3. Printing dissolvable support optimization

If you want to save printing time and material costs when printing dual prints with dissolvable support, set up the support interface. It will create two different support structures, one of them is a small interface using the water-soluble material and the other part is a normal structure with the material of the model, reducing the tool changes and saving support material.

Conclusions

- Don't increase the printing speed over the recommended values.

- Check the specific speed values like the wall speed and the infill speed, if you want to speed up your prints safely.

- Reduce the infill density and use infill patterns that optimize the resistance like triangles, cubic, or gyroid.

- Use bigger hotends and increase the layer height, the extra amount of filament extruded helps to reduce the printing time a lot.

- In dual prints, disabling the prime tower and increasing the standby temperature can help to reduce the tool change time.

- If you're printing soluble supports, set up the support interface to save printing time and material.