Understanding the Infill - BCN3D Stratos

| Remember that BCN3D Cura will not receive new software updates. Please download BCN3D Stratos our new slicer for improved performance. |

Find out More Information about This Parameter:

Infill extruder

Density

Pattern

Infill Percentaje Overlap

Infill before the walls

Minimum infill area

Infill Extruder

Allows you to choose the extruder for printing the filler.

At a practical level, it gives the option that the piece has an outer material that resists environmental conditions and an internal material that resists physical efforts, such as a piece of TPU with an ABS interior, where the ABS would provide structural resistance and the TPU would be the exterior subjected friction.

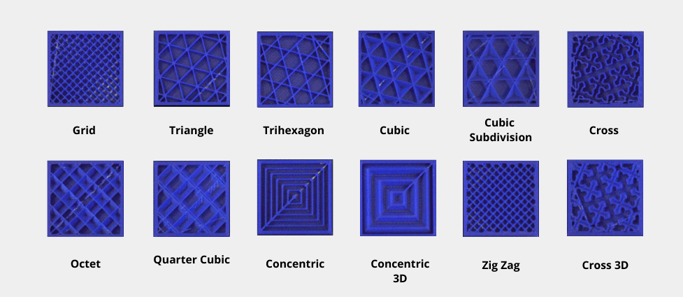

Density

Is the amount of material that is used inside the impression. This value is indicated in percentage.

Tips to modify the infill density:

- Pieces that do not require strength can use a density of 20% or less.

- the 100% infill is not necessary to achieve the maximum strength of the printed piece. There are other parameters that improve resistance

- Even though the piece is not going to withstand force, the filling must be higher than 0% to support the upper layers that form the roof.

- To increase the flexibility of the printed model it is recommended to use less than 20% infill.

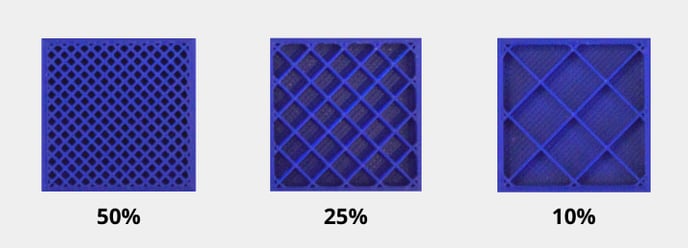

Pattern

The patterns directly influence the mechanical resistance of the piece. In this section, you can choose between 12 available patterns.

Below you will find a list of commonly used fill patterns:

Lines: For fast prints, this pattern is ideal, it consumes less material, and offers strength in the X / Y plane.

Grid: In appearance, it looks like the line pattern, however, it is significantly stronger. It takes a little longer to print and consumes more material.

Tri-hexagonal: It is the most resistant 2D filling. It creates hexagons with embedded triangles in the X / Y plane.

Cubic: Creates 45º rotated stacked cubes that offer excellent resistance in all directions. However, it takes more time and material.

Octet: In resistance, it is similar to the cubic infill, but due to its construction in the shape of square pyramids, it gives better support for the ceiling of the model.

Concentric: It consumes less material than the rest of the patterns and is the most suitable for printing flexible pieces. It requires little printing time as it is an internal spiral structure.

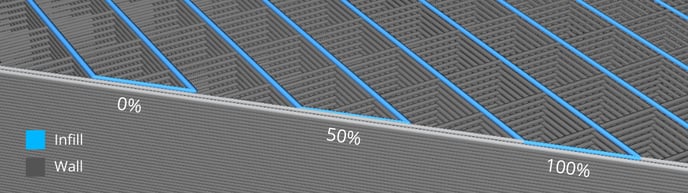

Infill Overlap Percentage

Is the percentage of filling that is printed on the walls, allowing an increase to the resistance of the piece at the expense of having over-extruded areas.

Reducing this parameter allows the elimination of filling marks on the walls, something very useful for aesthetics and for dimensional quality.

Infill before the Walls

.png?width=688&name=prueba4%20Cropped%20(1).png)

With this parameter, you can change the order in which the perimeter and padding are printed.

On:

Facilitates the printing of overhangs and bridges.

Increases the strength of the walls in the X / Y directions.

Off:

Reduces surface marks caused by filling.

The measurements of the piece assimilate better to the design.

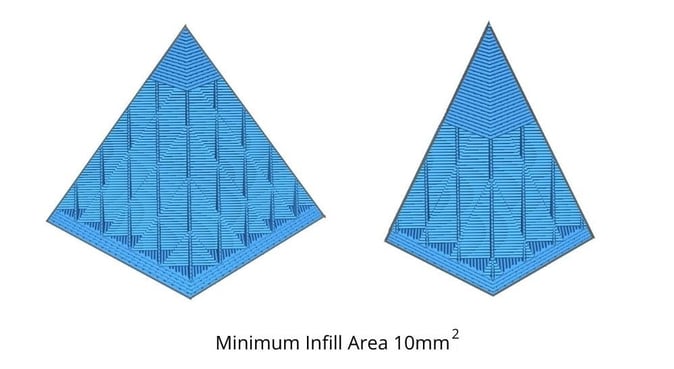

Infill Minimum Area

This option lets small areas of the model be printed fully solid, instead of using the infill density setting.

This is ideal for increasing the strength of thin towers, narrow areas, and areas that have many continuous holes.

Forum community

Need more tips? Check out our forum community for help.

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done.

Maintenance Plan (Epsilon Series)

Maintenance Plan (Sigma Series)

Maintenance Plan (BCN3D Sigmax)

Maintenance Plan (BCN3D Sigma)

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |