In this article you will learn how to master BVOH

This article contains advanced information regarding BVOH. The default settings for our BCN3D BVOH have been tailored for good quality and reliable results, and are fully tested by our laboratory. These tips complement those settings to ensure the best quality in printing with BVOH.

Tip: Take a look at the material compatibility list, to help you understand which materials you can combine in dual printings with BVOH:

Proper storage is the best way to ensure the quality and longevity of your BVOH

BVOH is highly hygroscopic, which means it absorbs a lot of moisture from the environment and quite quickly. When this happens, the BVOH polymeric chains break down as the material heats up, making it granulous and not smooth. This can cause clogging and various printing quality issues.

If you want to prevent this from happening and learn a bit more, check out our guide on how to solve this common problem: Printing issues related to humid filament

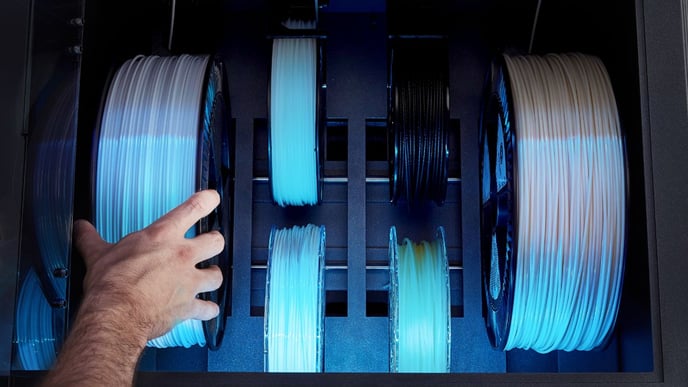

BVOH is quite sensitive to UV rays and it degrades if exposed to natural light for a relatively short period of time. Be sure to store BVOH coils in a dry and dark place, such as the Smart Cabinet.

Set supports properly

As said before, BVOH is used as a support material, but there are some settings that be aware of in order to have the best overhang quality.

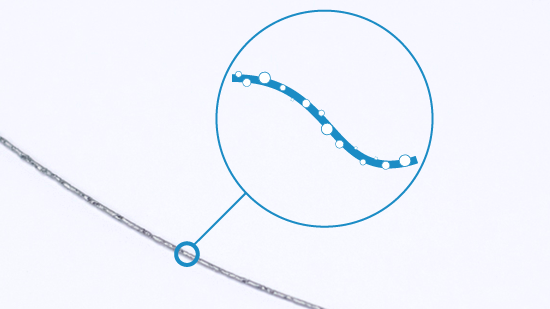

If you want the overhangs supported properly, you must make sure that the contact with the BVOH supports is optimal. You can increase or decrease support x/y distance and minimum support x/y distance in the settings so the piece material hangs less.

The support distance between the print and the z-axis is crucial when it comes to surface quality. Usually, when the support and model are printed with the same material, it's better to have a weak attachment. Nevertheless, BVOH is a water-soluble material so you can make the attachment as strong as you want.

You can reduce by adjusting the support settings the Z distance to 0mm.

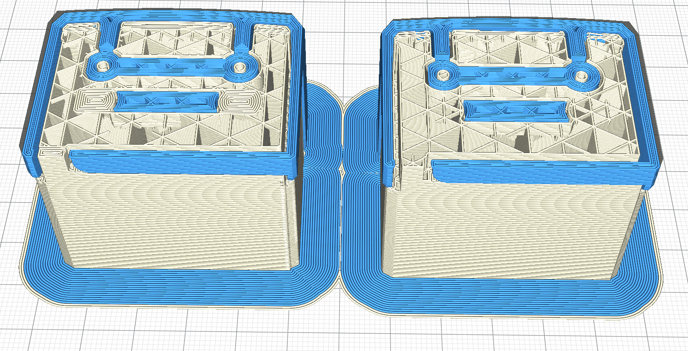

In the previous image, you can see how the support density increases when you set a 0.4mm distance. This happens because it starts printing them earlier, so you can have the right space later between the print and the supports.

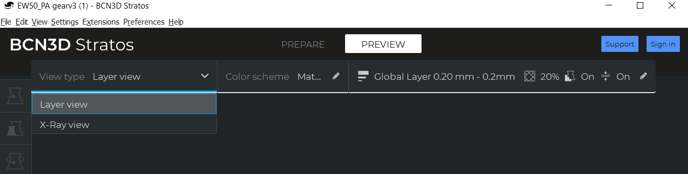

To be able to see how the supports are generated, you can access the layers view, from the view drop-down menu that appears in the upper right corner after slicing the geometry.

Printing parameters to be aware of

In addition to the above settings, there are a few more parameters that can help you achieve the best results depending on the model geometry:

- Overhangs support angle: If you want the overhangs to have a better surface quality you can add supports to help the material stay in the right position. You can reduce the angle by clicking on the support settings tab so you obtain more supports.

- Support horizontal expansion: This setting extends the structure support horizontally, making it more stable. Increase this parameter to get better supports. A 2 mm value should work.

- Printing temperature: BVOH struggles to stick on flat printing surfaces especially if they are made from PLA, which induces warping. To prevent this you can increase the printing temperature of BVOH so it adheres better to the material.

If you want to save filament and time you can print your supports with the main material filled with BVOH. How to optimize support materials usage

Hotend cleaning is key to preventing clog issues

We usually recommend cleaning the hotends from time to time or after changing the material used. In spite of this, when it comes to water-soluble materials such as BVOH, it is recommended to clean the hotend after each print to avoid clogs.

How to clean the hotend (Epsilon Series)

How to clean the hotend (Sigma Series)

How to clean the hotend (BCN3D Sigmax)

How to clean the hotend (BCN3D Sigma)

How to properly dry BVOH

It is required to keep BVOH dry to achieve the best printing results.

BCN3D created the Smart Cabinet to keep all types of printing material dry. Be aware, that if you have other means of keeping your filaments dry, don't dry for more than 16 hours or at a temperature higher than 60ºC. Otherwise, your BVOH will become highly brittle.

How to effectively dissolve it

Once the print is done you'll need to remove the support material. The following steps will save you time during this process:

1. Remove all the BVOH you can with your hands or pliers to save time.

2. Immerse your print in hot water to reduce dissolution time. The water cannot exceed 50ºC when your material is PLA or Tough PLA.

3. Slowly moving the print back and forth in the water can speed up the process.