Why it happens and how to notice, avoid and deal with it

Underextrusion, Stringing, Bubbles, and Oozing are all issues related to the presence of humidity in your filament. If your spool is not dry, you can expect low print quality and fragile prints. In this article, we're going to cover why it happens, how to spot the issue, and how to solve and prevent it.

Know if your filaments are wet

The first thing you need to know when troubleshooting is the symptoms of each problem. After reading this article, you'll be able to notice whether or not your filament is wet.

The most obvious sign of humidity is noticing the material is not smooth and there are tiny bubbles inside of it. These bubbles are formed by the evaporation process as the moisture inside the filament creates steam as the filament is heated.

You can also notice the filament is affected by humidity if the material continues to ooze out, even after the extruder motor has stopped pushing it through the hotend.

Another more subtle but noticeable observation of humidity issues is if you hear sizzling or popping noises coming from the nozzle while the filament is extruded, it means the filament is humid, the spool needs to be dried.

What happens when moisture is absorbed by polymers

All the materials that are printed with BCN3D machines are polymers. These materials have a tendency to absorb moisture from their environment, some more than others, but they all do.

Having moisture in the filament can cause issues in 3D printing, especially with more hygroscopic materials such as PA, TPU, PVA, or BVOH. Other materials like PLA, PET-G, or ABS are also susceptible to absorb moisture from the air, but at a lower rate.

So, what exactly happens when the filament is affected by humidity? Why does it have such a large effect in 3D printing?

There are two main reasons: Foaming and Hydrolysis.

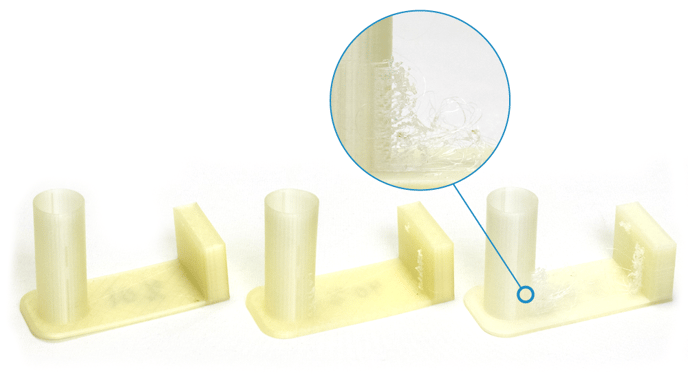

- Foaming: is the phenomenon in which the caught moisture evaporates when the filament is heated. In this case, air bubbles are formed in the material, and the print comes out with strings and blobs, bad quality and much weaker than desired.

* Foaming representation: When it happens, the filament has a bubbly appearance.

* Foaming representation: When it happens, the filament has a bubbly appearance.

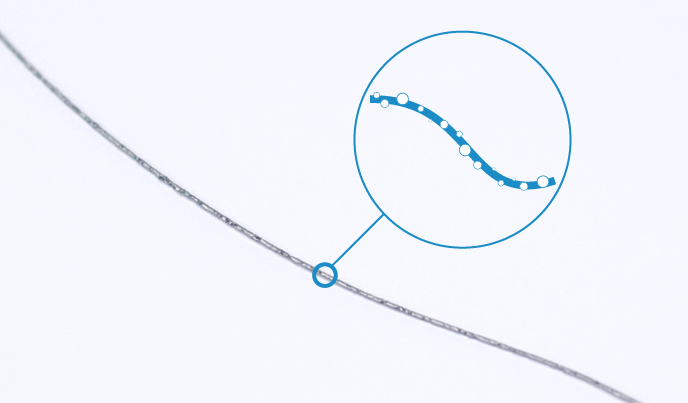

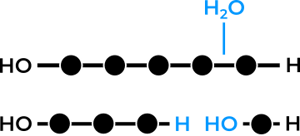

- Hydrolysis: is the name of a reaction that happens when there are water molecules present in the polymer structure. In short, when water is absorbed by the polymer, it breaks up all the secondary molecular bonds in the polymer, changing it to a much simpler form, monomers.

* Hydrolysis reaction schematic: Water molecules are placed in between each monomer and break down the polymer structure.

This makes the material composition and properties change, making the filament harder and brittle, in turn becoming more likely to clog the hotend as the fusion temperature increases.

How to dry filament and store it

So, how can one fix these print quality issues? The answer is simple. You need to dry out your filaments and know how to store them properly. To dry your spools you can use a regular preheated oven at a specified temperature to each filament.

If you don't want to mix up your cooking appliances with your 3D printing gear, our BCN3D Smart Cabinet gives you the all-in-one solution for drying and storing your filaments in perfect condition while they are not in use. It is specifically designed for an extensive use and to improve the reliability of your printers.

You can also consider buying and modifying a food dehydrator, or purchasing an actual filament dryer, specifically designed for 3D printing materials, although the results might not be as good as having the Smart Cabinet installed in your workspace.

It is also recommended to unload the filament after a print job is finished to prevent it from absorbing moisture, as the part of the filament that stays out of the cabinet will be unprotected.

If you don't have the Smart Cabinet, make sure to unload the spool and store it as previously described.

Here's a drying chart that will help you along your 3D printing journey:

Warning! Always take into account the material of the spools, you'll see the material listing normally specified on the spool. If your spool is made out of recycled PLA, or a material that has a lower vitreous transition temperature than the actual filament, lower the drying temperature (for example, if you want to dry PA in a recycled PLA spool, you should dry it at 45ºC for a bit more time).

|

Filament |

How to dry it |

How to store it |

Before Printing |

|

PLA |

45ºC for 6 hours |

No special considerations |

Just load it up! |

|

TPLA |

45ºC for 6 hours |

No special considerations |

Just load it up! |

|

PVA |

50-55ºC for 12 hours |

Dry airtight container with desiccant sachet |

Dry it a bit |

|

BVOH |

60ºC for 4 to 16 hours |

Dry airtight container with desiccant sachet |

Dry it a bit |

|

TPU |

50-55ºC for 12 hours |

Dry airtight container with desiccant sachet |

Dry it a bit |

|

PET-G |

65ºC for 6 hours |

No special considerations |

Just load it up! |

|

ABS |

80ºC for 6 hours |

No special considerations |

Just load it up! |

|

PA |

80ºC for 12 hours |

Dry airtight container with desiccant sachet |

Dry it a bit |

|

PP |

45ºC for 6 hours |

No special considerations |

Just load it up! |

|

PAHT CF15 |

80ºC for 12 hours |

Dry airtight container with desiccant sachet |

Just load it up! |

|

PP GF30 |

45º for 6 hours |

No special considerations |

Just load it up! |

|

PET CF15 |

45º for 6 hours |

No special considerations |

Just load it up! |

Conclusions

- Keep your filaments stored in an airtight box with desiccant to avoid the filament absorbs humidity

- Is highly recommended to dry filaments like TPU, PVA, BVOH, PA, and PAHT CF15

- The humidity can cause underextrusion, clogs in the hotend and weak printed parts

- If you want to know a bit more on this matter, check out this whitepaper: The Importance of Optimal Filament Storage Conditions and an In-depth Comparison of Well-known Filament Drying Methods