The IDEX technology brings the possibility to print with two different materials or colors at once. This article will help you reach even cleaner results when printing in Dual mode and solve the main causes of the material contamination

Why the dual prints could be not clear?

Some common printing quality issues are related to the color overlaps in the Dual prints:

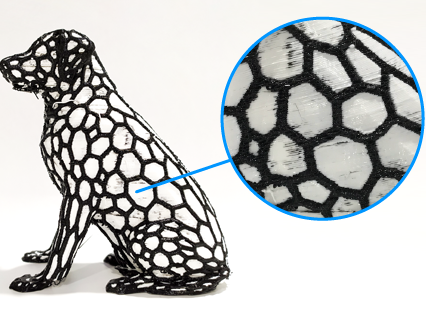

- Stringing: fine strings left around on the print can contaminate each material in the piece.

- Calibration issues: when the materials are not aligned due to a calibration issue, may cause the colors overlaps. Checking the calibration of the X and Y axis can help to solve the problem.

How to improve the quality of the dual prints

1. Ensure a good cleaning

All of our printers have purging buckets and on top of them, you'll find the Silicone Cloths, these are in charge of cleaning the nozzles.

These little wipes play a huge role in this, they are a component that tends to be overlooked and it is important to have them in the best conditions possible to keep the nozzle clean during the Dual prints.

Check that they are not broken and raise them just a bit so they clean the nozzle thoroughly.

- If your Silicone clothes are broken, feel free to get in contact with your distributor or our sales team to replace them.

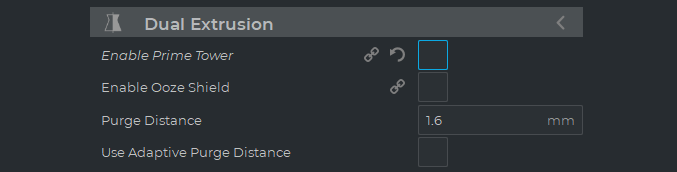

2. Learn when to use purge towers

For prints that have a small number of tool changes, you should leave the purge tower activated, as the filament that's loaded in the idle printhead is kept at a high temperature, it will absorb more moisture than usual, and crystallize inside the nozzle, thus making a low-quality print. The purge tower helps to purge this worn-out filament while keeping the printed part clean.

For prints with a lot of tool changes, this is not necessary, as there's not going to be enough time for the filament to absorb moisture or crystallize. Disable the purge tower, this will save you printing time and material that can be used for other prints.

3. Check the travel settings

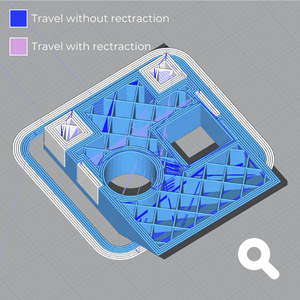

The way the travel movements are configured is crucial to getting cleaner results. When the hotend travels over the model could ooze material, leaving strings of material in undesired places. To avoid it, you can try the following configuration tips:

- Modify the combing mode: it is enabled in all the profiles to reduce the number of retractions during travels over the model. It is the main cause of color contamination on the top and bottom surface of the model, so you can change it to "No skin" or turn off this mode to avoid the problem.

- Enable avoid printed parts when traveling: if the combing mode is enabled, you can select this option to avoid or reduce the number of travels without retractions over the printer parts. It could increase the print time.

4. Adjust the retractions

- Increase the maximum retraction count: in dual prints is very easy to reach this value, causing the printer doesn't retract the material leaving strings. A value of 20 retractions could be enough, however, you can check it on the preview screen.

- Increase the retraction distance: if the material is not completely retracted from the nozzle during travel, the hotend could ooze a little bit of material. Increasing the retraction distance to 7mm helps to avoid this problem.

5. Use a small hotend

To print cleaner dual prints is necessary to calibrate the printer correctly to avoid misalignments in the colors. However, a big hotend can cause reduce the accuracy of the prints, mixing the materials on the surface of the model.

- 0.4mm and 0.6mm are ideal to print accurate dual prints without color contamination.

Conclusions

- Keep your silicone cloths in good shape to ensure that the nozzles are clean during Dual prints

- Enable the Prime tower to wipe the hotend before printing the model

- Set the Combing mode at "No Skin" or "Off" to avoid material contamination on the top and bottom surface of the model

- Enable the Avoid printed parts during a traveling to avoid strings or material mixing during tool changes

- Increase the Maximum retraction count until the blue travel lines disappear, to retract the filament each time that would be necessary during the print job

- Increase the retraction distance to 7mm to ensure that the filament is correctly retracted during a travel

- Use 0.4mm or 0.6mm hotends to avoid material contamination due to the lack of accuracy during the printing