How to fix Stringing/Oozing

In this article you will learn how to proceed if you are experiencing stringing/oozing

What is Stringing and why it happens?

|

Stringing, also known as oozing, is easily noticeable, as you'll see fine strings left around on the print. These fine strings look like cobwebs or strands of hair. This is normally due to the filament oozing out of the print head while it's traveling. As the print head travels across the build volume, some filament may ooze out in small quantities. This will solidify and stick to the printed parts. |

Normally stringing shouldn't happen, however, it will sometimes happen depending on which filament you are using. PET-G is notorious for stringing, and hygroscopic materials such as TPU or Nylon may have stringing issues if they are not well-conditioned.

There are many ways to fix stringing. Luckily, it's quite easy to solve. Let's look at all the variables that can influence stringing.

How to fix it

1. Enable all the settings in BCN3D Stratos

You'll have to tweak a lot of settings in BCN3D Stratos. If you don't see some of the settings listed here, update it to the latest version.

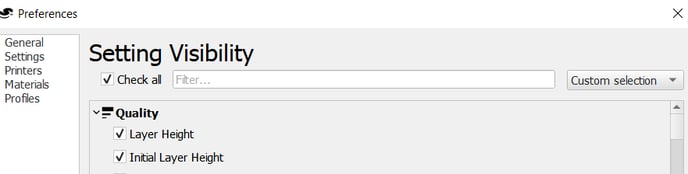

Go to Settings/Configure settings visibility and click on the "Check all" box.

2. Adjust the Retraction settings

|

No retraction |

With retraction |

Enabling retraction is key to solving stringing. Retraction is a feature that is enabled in BCN3D Stratos by default. This particular setting will make the extruder motor pull the filament back before any movement, preventing it from oozing while the head is traveling. If you still experiencing stringing issues with the retraction enabled you'll need to tweak the retraction settings. These are located in Custom configuration mode, in the Material menu. |

- Retraction Distance: It is the distance at which the filament is pulled back. If you increase its value, it will reduce stringing, but if you increase it too much, your print will have gaps on its walls. Try to find the sweet spot by performing printing tests.

- Retraction speed: The speed at which the filament is pulled out of the nozzle. If it's too slow, the material has a lot of time to ooze out while retracting, if it's too fast, the extruder motor gears can grind the filament and cause underextrusion.

- Prime speed: The opposite of retraction is priming. This movement pushes the filament back in the nozzle exit so it can continue extruding. If you lower this speed, the filament will have a more controlled extrusion. If it's too fast, oozing will also occur at the start of the extrusion path, leaving behind a blob of filament.

3. Set the right temperature

As the temperature increases, the filament becomes more viscous and runny, which means it will be easier for it to ooze and cause stringing even after tweaking the retraction settings. A lower temperature will leave fewer strings, however, if you set it too low, underextrusion will appear.

Once you notice stringing, you can decrease the temperature while the printjob is running by going to Settings/Temperatures and lowering the extruder temperature in 5ºC steps until you observe it not stringing anymore. You can run print tests to find the right temperature for a particular filament.

4. Check the travel speed

The travel speed can also affect stringing. If the print head takes too long to go from one point to another, stringing will be more likely to happen, as the molten plastic will have more time to ooze. A travel speed of 150mm/s is ideal for most filaments.

5. Keep your hotend clean

/maintenance-task-clean-hotend-extruder-3d-printer-bcn3d%20Cropped.png?width=688&name=maintenance-task-clean-hotend-extruder-3d-printer-bcn3d%20Cropped.png) Remember to clean the hotend regularly, especially when loading it with different materials. Also, clean the nozzle with a brass or copper brush before printing to prevent any residue from sticking to your printed part.

Remember to clean the hotend regularly, especially when loading it with different materials. Also, clean the nozzle with a brass or copper brush before printing to prevent any residue from sticking to your printed part.

- Click on the picture corresponding to your printer type know how to clean the hotend:

| How to clean the hotend | |||

|

|

|

|

Conclusions

- If you're using custom profiles, use the retraction settings of the recommended profiles to avoid stringing issues.

- Increase the retraction distance up to 7mm, the retraction speed to 25mm/s, and the prime speed to 18mm/s to reduce the strings in your prints.

- For TPU, be careful with the retractions. Keep the retraction distance under 4mm and the retraction speed below 20mm/s.

- In PET-G, you should lower the retraction speed as it is a very viscous filament, and if pulled out quickly, it will make even more stringing.

- Reduce the print temperature in steps of 5ºC until the strings disappear. Be careful to don't reduce the temperature below the recommended print temperature values.

- Set the travel speed at 150mm/s to avoid the nozzle oozing over the printed part.

- Keep the nozzle clean to avoid residues sticking in the part and clean the hotend when you change the material.