In this article you will learn to fix issues that result in the filament being damaged before reaching the hotend

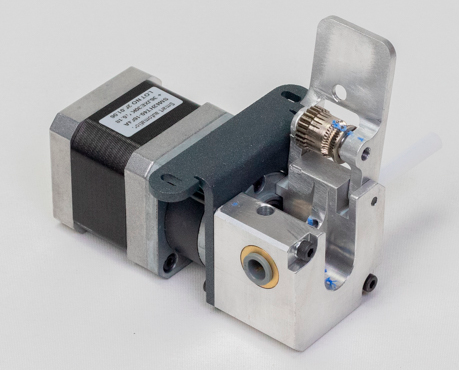

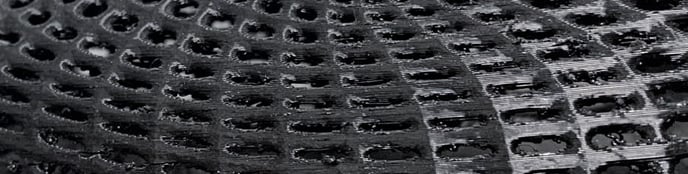

BCN3D printers extrude the filament by pushing it between two gears that spin. The gears bite into the filament to move it up, but in the case, the filament gets stuck, the gears will continue spinning and consequently damage the filament. You can identify this problem by looking at the filament after it has passed through the motor.

In this article, you will find the most common problems and some tips to fix it.

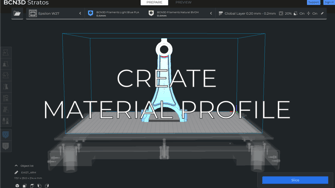

Check the material configuration

In most cases, the wrong Stratos profile configuration can cause underextrusion or other printing issues that result in the material being grinded. We recommend the default profiles in Stratos. These profiles are made to ensure the best print quality. If you are experiencing filament grinding with our material while also using our default profiles, go to the next point.

1. Hostile retraction settings

The retraction settings are usually tweaked to avoid printing issues like stringing but a very high retraction speed or a very long retraction distance can cause grinding issues.

To avoid this problem is necessary to retract the filament slowly, reducing the retraction distance and the retraction speed:

- We recommend a maximum retraction distance of 7mm.

- You can also try to reduce by 10mm/s the retraction speed to see if the issue is solved.

2. Low printing temperature

If the material is not being melted at enough speed, it will get stuck on the hotend while the motor keeps pushing which results in it being grinded, try to increase the temperature by 5ºC or 10ºC to help the filament melt in time.

-

Warning! Check the datasheet of your material before increase the temperature, a high temperature can burn the filament inside the hotend and clog it.

If you need the technical sheet for the BCN3D filament, you can check the filament category in our knowledge base: Filaments

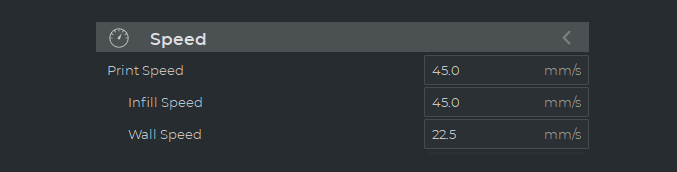

3. Printing Speed

Printing at high speed means that the gears on the motor will spin faster. During long-time prints, the filament can get grinded by the friction between the components of the extruding system and the high speed of the motor.

To fix it, you can reduce the printing speed allowing the extruder motor to work at lower pace; try to reduce the speed by 50% to check if the problem is gone or decrease the speed in steps by 10mm/s.

Solving mechanical issues

The configuration is not the only cause of the grinding problems, if you have already checked the steps above, the following steps will help to solve any mechanical issue that cause grinding.

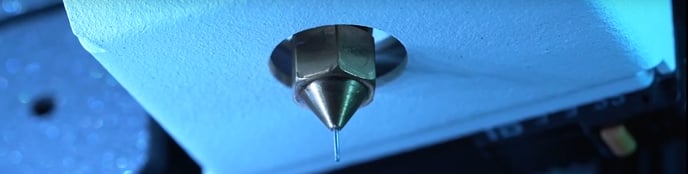

1. Hotend clog

/maintenance-task-clean-hotend-extruder-3d-printer-bcn3d-1.png?width=688&name=maintenance-task-clean-hotend-extruder-3d-printer-bcn3d-1.png)

If you use different materials or the wrong configuration, parts of the filament can get stuck on the hotend and produce grinding on the filament, to avoid and solve it, is recommended to clean the hotend frequently.

- Click on the picture corresponding to your printer type know how to clean or unclog the hotend:

2. Maladjusted extruder motor thumbscrew

.png?width=688&name=extruder-motor-epsilon%20Cropped%20(1).png)

If the extruder motor is not properly adjusted, the gears might not be able to grab the filament or the filament gets crushed by the high pressure, in both cases causing underextrusion.

To adjust it properly, fully screw the knob and then lose one turn.

3. Damaged bowdens

The filament travels through the bowden which causes some friction during all its curves; if the bowden is damaged, the friction at the damaged point can cause the filament to get stuck. Visually check if the bowden has a notch. Insert a filament through the bowden to check if it can flow easily.

Get in contact with your distributor or with the BCN3D support team to get a new one in case it is faulty.

Extra tip: Remember to clean the extruder gears

if you had experimented with this issue to remove the dust that must have on the gears and avoid underextrusion issues related to the lack of traction of the filament

- To clean the extruder motor, click on the picture that corresponds to your printer:

Conclusions

- Use the recommended profiles to check if the problem is coming from the printing settings or the hardware.

- Adjust the temperature, reduce the printing speed below 50mm/s and avoid aggressive retraction settings.

- Clean your hotend each time that you need to change the type of material to avoid clogs.

- If you still experience filament grinding issues, get in contact with our support team by filling this form.

/r17-extruder-screw.png?width=688&name=r17-extruder-screw.png)