How to unclog a hotend

Hotend clogs are one of the most frequent issues in FFF (Fused Filament Fabrication) 3D printing. Here we will talk about why the hotends get clogged and the different ways you can solve this.

| Tools | |

|

Nozzle cleaning needle |

Allen key 2mm |

How to know if the hotends are clogged?

There are many reasons why the hotends get clogged, so it is important to take in consideration that changing the hotend in the first place is not the definitive solution on this matter. Locating the issue is important to find the best solution to this issue.

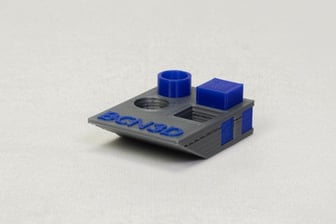

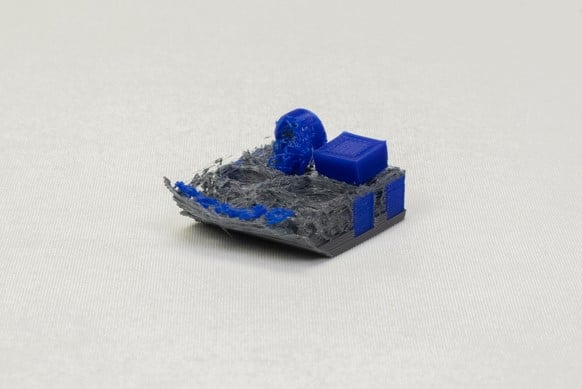

Clogs can happen partially or totally, and you can diagnose if it's a partial clog or a total one by observing the prints:

|

|

| Partial Clog | Total Clog |

- Partial clogs happen normally in the middle of the printjob, even if the extrusion is regular and good, you spot that there are layers missing in the print.

- Total clogs, in the other hand, present a sudden interruption of the extrusion, and are a bit more difficult to fix.

Another sign that can tell you the hotends are clogged is clicking sounds coming from the extruder motor. The clicking sound means that the motor itself doesn't have enough force to push the filament through them, this can also have many other causes related to the underextrusion issues.

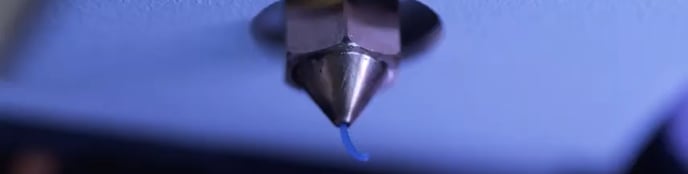

You can prevent clogs if you see that the filament curls up while it is extruding or it is not extruded consistently by simply cleaning the hotend. Keeping a good maintenance of the hotend is key to not have clogs in a long time.

Removing the clog

There are two main methods of dealing with this issue. To choose the right method, see whether or not it is possible to load/unload the filament. Partial clogs can usually be melted out or be removed with a simple Nylon clean, more complex clogs that prevent even loading of the filament call for more unorthodox methods.

Method 1: Clean the Hotend

If you can load and unload the filament, but you are still experiencing some clogs, try cleaning the hotend with Nylon.

- Click on the picture corresponding to your printer type know how to clean or unclog the hotend:

Method 2: Purging the clog

When you experience clicking noises and the filament still doesn't come out the nozzle, try the following method:

1. Unload the filament. If you can't unload it, these unloading filament articles will help you on this:

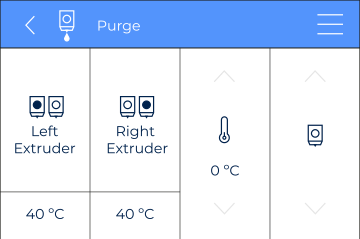

2. In the Purge menu (Utilities/Filament/Purge) raise the temperature about 40-50ºC above the default printing temperature.

3. When the temperature is reached, wait for 3 minutes, the filament should start oozing out. Use a fine, nozzle cleaning needle for 3D printing and push it through the nozzle from below. Push in and out in multiple directions.

4. Try loading the filament again and see if the issue is solved or the clogging persists. If the needle didn't help in this, take out the bowden tube and push some nylon through the hotend.

5. Let the hotend cool down and pull out the nylon when it goes down to 70ºC and pull it out as in a normal Nylon Cleaning.

Conclusions

- Clean your hotend each time that you need to change the type of material to avoid clogs.

- Keep your filament dry and correctly stored to avoid clogs related to the humidity.

- For total clogs, use a nozzle cleaning needle or a 2mm Allen key to push the clog through the hotend.

- Keep the cooler fans free of dust or strings of filament.

- If none of this works, swap the hotends from one head to the other, if the issue moves to the other head, it's time to replace the hotend.

- If the clogs persist on the same head, get in contact with the support team.