How to fix Underextrusion

The most common printing issue in 3D printing. It consists of a lack of extruded material in the printed part that will show as missing layers or spongy prints. In this article, you will learn how to fix this issue

What is Underextrusion and why it happens

Underextrusion, as the name states, happens when the hotend extrudes less filament than desired. This issue directly affects the quality of the printed part, making it look rough, incomplete, and weaker than usual. There are many factors that can make this happen.

|

We recommend using BCN3D filaments with our 3D printers. The default BCN3D Stratos profiles for BCN3D filaments are tailored by our Lab to deliver the best quality and reliability for your prints, so if you find underextrusion in one of our filaments, it's possible that the filament simply needs to be dried, or that there's a problem in the hardware itself. |

How to fix it

Being that this underextrusion has many different causes, troubleshooting it can be complex. Here's a list of all the causes and ways you can resolve them. If one method does not solve the issue, move on to the next one.

1. Update BCN3D Stratos

BCN3D Stratos is constantly updated with new profiles that improve the quality of the service. Pay attention to the release of new versions of BCN3D Stratos, and make sure to keep it updated.

To know how to download and install Stratos, visit this article: BCN3D Stratos.

2. Update the Firmware of your printer

|

/bcn3d-install-firmware-1.png?width=335&name=bcn3d-install-firmware-1.png) |

A printer with outdated firmware can have some bugs that may cause underextrusion. To upgrade the printer firmware, click on the picture corresponding to your printer type to check the corresponding article:

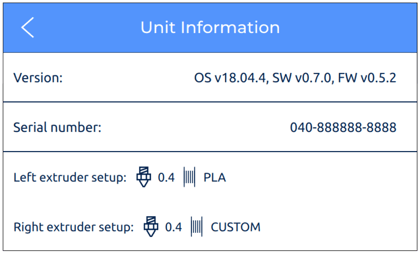

3. Adjust the printing profile for your material

To avoid underextrusion, we recommend the default profiles in Stratos. These profiles are made to ensure the best print quality. If you are experiencing underextrusion with our material while also using our default profiles, go to the next point.

If you are using custom profiles or filaments from a different brand, note that there are some factors that can also cause underextrusion:

- Printing Temperature: Normally if you find underextrusion, the first thing to look at is the printing temperature. To find the right temperature, you can print a temperature tower test and change the temperature until you find the best quality.

- Printing Speed: If the printing speed is too high, you'll notice that the hotend is not able to extrude enough material. Printing at 50mm/s is generally good for ABS, PLA, and PET-G, while other filaments may require slower speeds.

- Retraction Settings: Retraction is a feature in which the filament is pushed out of the nozzle a bit to prevent oozing during travel. If the number of retractions, the retraction distance or speed is excessive, you might find gaps appearing on the walls of the print or experience hotend clogs.

- Take into account that underextrusion also depends on the filament and room humidity, room temperature, and manufacturing defects.

- For third-party materials: feel free to contact their manufacturer to get a printing profile for your filament, they know their filaments more than anyone else.

To prevent other issues with our filaments, check the following tips and tricks articles for each material:

| Standard Materials | PLA | TPLA | PVA | TPU | BVOH | PET-G | |||||

| Technical Materials | ABS | PA | PP | ||||||||

| Composite Materials | PAHT CF15 | PP GF30 | PET CF15 | 316L | 17-4 PH | ||||||

4. Check the bowden tubes

The bowden and the filament are in constant friction. Occasionally an excess of friction can stop the filament and cause underextrusion. Check the bowden and whether it is bent or has a bad shape.

If this is the case, contact us or your reseller of choice to get a new bowden tube.

5. Check the cooling of your hotend

An excess of temperature in the printing head can cause a clog in the hotend, this will cause a gradual underextrusion along with the print until no filament is extruded. Check if the cooler fans are clean and use a vacuum cleaner or a brush to ensure that nothing is blocking the fan.

- To check if the fans are working properly, click on the picture corresponding to your printer type:

| How to check the operation of the cooler fan | |||

|

|

|

|

- In some cases, room temperature can influence, especially with PLA. Check that the room temperature is not over 25ºC and there's correct airflow in the room.

6. Clean or change the Hotend

A constant underextrusion throughout the piece shows that the issue is likely located in the hotend, specifically if you use different materials in the same hotend because it can clog over time, sometimes this is accompanied by a repetitive clicking noise. You should always clean the hotend with nylon every time you change material types.

- Click on the picture corresponding to your printer type know how to clean or unclog the hotend:

| How to clean the hotend | |||

|

|

|

|

| How to unclog a hotend | |||

If the problem persists, the hotend is probably damaged. Try to swap the hotends and print, if the problem changes to the other side, you will need to swap it out for a new one. The following articles have information about this process:

- Warning! Hardened steel hotends shouldn't be used for non-abrasive materials like PLA, ABS, PET-G, TPU, etc. For these materials, it's best to use brass-tipped hotends.

If the hotend is burnt or damaged, it is likely that the extruder board has a problem. Continue to the next section to find more information about this.

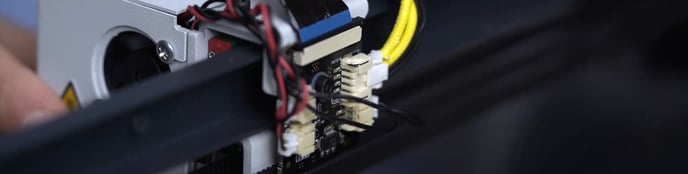

7. Check the Extruder Board

This component sends the signals that control the hotend temperature and the funcioning of the fans. If the extruder board doesn't work properly, it can lead to random underextrusion and overheating issues during the print job.

To check if the problem is the extruder board, swap them. If the problem moves to the other printing head, you will need to swap out the extruder board in question for a new one.

- Click on the picture that corresponds to your printer to know how to swap and change the extruder boards:

8. Adjust, clean, and check the extruder motor

.jpg?width=688&name=check%20extruder%20Cropped%20(1).jpg)

If the extruder motor can't push the filament correctly, the result will be underextrusion. Keep the motor clean and check that the thumbscrew is correctly adjusted.

- To fix the extruder motor, click on the picture that corresponds to your printer:

If the problem continues, swap the extruder drivers and check if the problem moves from side. Click on the picture that corresponds to your printer to know how to swap the drivers:

Conclusions

- Keep your printer and slicer updated to avoid bugs that could cause underextrusion.

- Use the recommended profiles to check if the problem is coming from the printing settings or the hardware.

- Keep your filament dry and correctly stored to avoid underextrusion issues related to the humidity.

- Adjust the temperature, reduce the printing speed below 50mm/s and avoid aggressive retraction settings.

- Clean your hotend each time that you need to change the type of material to avoid clogs.

- Keep the cooler fans free of dust or strings of filament.

- Remember to clean the extruder motor if you have experienced underextrusion issues.

- If you still experience underextrusion issues, get in contact with our support team.