In this article you will learn some information to master PP GF30

Note: This article contains advanced information related to the BCN3D PP GF30. The default settings of our BCN3D PP GF30 have been adjusted for good quality and reliable results, and are fully tested in our laboratory. These tips complement those settings to ensure the best print quality with PP GF30.

PP GF30 (Glass Fiber Reinforced Polypropylene) is a composite material that offers a greater strength and stiffness than PP. Its high chemical and mechanical resistance makes this filament ideal for printing parts for outdoor use that need to withstand high-stress situations.

This material is a bit difficult to work with but with these tips you will be able to print it with good results.

Tip: Check this material compatibility chart, it will help you choose the materials that fit best with PP GF30:

Combination of supported materials

Adhesion of the first layer and how to remove the print

Making the first layer in PP GF30 is a challenge. Good adhesion must be guaranteed to be successful in your prints. PP GF30 has a high shrinkage constant, and if it cools too quickly, it will warp and peel off the bed. This article will help you with this problem:

How to fix first layer problems

To prevent this from happening, apply a good amount of Magigoo and preheat the build surface, so it's at the same temperature and the build volume is hot. Make sure the printing surface is flat and well calibrated.

Before you take out your finished print, let it cool as slow as possible so it shrinks evenly and tensions ease. Once cool, carefully remove the print. Here are some more tips to help you remove your impressions:

Prevent warping and cracks

PP GF30 has a high shrinkage constant, this means that it shrinks a lot when it cools down. This can cause the print to warp and create cracks. To prevent this from happening, PP GF30 should be printed in a closed, warm environment, without cooling.

The PP GF30 exhibits less warping if the models are slightly tilted and there are no 90° overhangs. For more information on warping, check the following article:

Tips to correctly adhere the print.

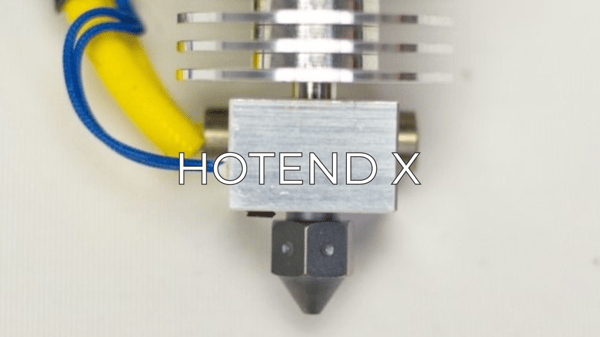

PP GF30 contains fiberglass and is quite abrasive. It is recommended to print it with our Hotend X, otherwise it will wear out the usual hotends making them unusable in a short amount of time. Check this article if you want to learn a little more about why you should print this filament with our Hotend X:

Post-processing with PP GF30

If you need to post-process your print, such as removing blemishes or remaining threads, you can use a scalpel and they will come off easily. If you intend to sand or polish your PP GF30 part, you should wear safety glasses and an FFP3 respirator to prevent particles of this material from entering your eyes or lungs.

Forum Community

Need more tips? Check out our forum community for more info about this.

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done.

Maintenance Plan (Epsilon Series)

Maintenance Plan (Sigma Series)

Maintenance Plan (BCN3D Sigmax)

Maintenance Plan (BCN3D Sigma)

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

You can help improve the BCN3D Knowledge Base.

If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :)