In this article, you will find a list of procedures and tips to help you get the print to adhere correctly to the build plate. With these tips, you will avoid a variety of problems that occur in the first layer.

What are first layer problems and why do they occur?

Warping

Is the partial lifting of some areas of the piece from the printing surface. This can be caused by a violent contraction of the material or a wrong calibration of the Z-axis.

This phenomenon can be differentiated when the first layer is not sufficiently attached to the printing surface or the piece "curves" after a while.

Elephant's foot

Refers to an excess of material in the first layer, commonly caused by a poor Z-axis calibration, as the hotend does not have the proper distance to extrude the material.

You will detect this problem if when you print the first layer you see that the material is very stuck and has a translucent appearance.

How to ensure the correct adherence of the piece

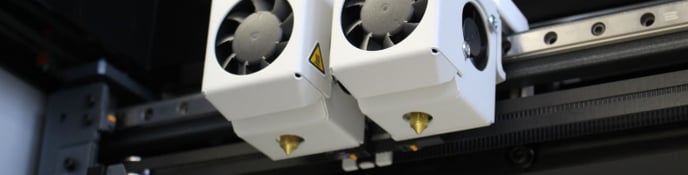

1. Calibrate the Z height of both heads

Make sure the nozzle distance is right by calibrating the Z height, go to Utilities / Calibration / Printer Calibration, and follow the steps that the screen shows.

- Click on the picture of your printer to know how to reach a perfect calibration:

2. Choose the right adhesive

Every material is different and has different properties, this also translates to adhesive compatibility. For example, Magigoo Original works great for PLA and ABS, but is not as good at sticking on PA.

- Check out each filament tutorial to find the right adhesive for each filament.

3. Make sure the printing surface is hot enough

Some materials will need a certain temperature in order to stick on the printing surface. Check that the printing surface is at that temperature. As a tip, let the printing surface heat up about 5 minutes before printing to ensure the build plate has an even temperature.

- General: Increase the temperature of the build plate gradually in steps of 5ºC to improve the filament adhesion.

- For Tough PLA and PLA: It is not recommended to exceed in more than 5ºC the temperature of the build plate due to possible deformations in the material

4. Some materials need a warm environment to be printed

ABS, PA, PP, and PPGF30 have a high contraction ratio, this makes them likely to warp up if they are cooled unevenly. This generates the need of an enclosed build volume.

Recommendations

- Note: The following recommendations are for ABS, PA, PP, PAHT CF15 and PP GF30

- Preheat the build plate at least 10 minutes before starting to print to make sure that the entire printing chamber is properly heated

- Make sure to avoid any air current around the printer and that the room temperature is between 15ºC and 30ºC.

Conclusions

- Warping could be caused by a wrong calibration and by the aggresive contraction of the material

- Elephant's photo is caused when the hotend doesn't have enough space with the printing surface

- Use the correct adhesive for your material to improve the adhesion

- Check periodically the calibration of the hotends and the printing surface

- Increase the temperature of the printing surface to avoid warping

- Preheat the build plate to increase the temperature of the build chamber and print correctly materials like ABS, PA, or PAHT CF15.