The following tips will help you to improve the quality of your TPU printing, increase the flexibility of your parts and avoid printing issues such as clogs.

Note: This article contains advanced information regarding TPU. The default settings for our BCN3D TPU have been tailored for good quality and reliable results, and are fully tested by our laboratory. These tips complement those settings to ensure the best quality in printing with TPU and other flexible materials.

1. TPU introduction

TPU (Thermoplastic Polyurethane) is an elastomer used for 3D printing components with flexible properties and is resistant to oil, grease, and abrasion. It is a popular material that can be found in mobile phone cases, wire jackets, hoses, automotive gaskets, footwear, and many other objects that require elasticity.

This material is soft and difficult to print, but once you get the hang of it, it delivers amazingly flexible prints that will impress your customers and friends. Here are some tips that will help you in printing TPU.

Remember to check the material compatibility in case you are going to print parts that need to be manufactured with TPU and another 3D printing filament.

2. Tips to improve TPU printing

Tip 1: Store it well

TPU is highly hygroscopic, which means it absorbs a lot of moisture from the environment, and quite quickly. When this happens, the TPU polymeric chains break down as the material heats up, making it foamy and not smooth. This can cause clogging and various printing quality issues related to the part's strength, as is shown in the next picture.

As an added tip, for longer print jobs, stuff some silica desiccant sachets inside the TPU spool to prevent it from absorbing moisture.

This filament is quite sensitive to UV radiation, and it will degrade if it's exposed to natural light during a fairly short period of time. Make sure to properly store TPU spools in a dry and dark place, such as the BCN3D Smart Cabinet or a closet.

Tip 2: Lowering retractions and printing speed

TPU is a very soft material, and if it moves in and out of the nozzle repeatedly it can get stuck in the hotend. Lower the retraction distance to 2mm and decrease the retraction speed to 20mm/s to prevent clogging and underextrusion, the less retractions the better. Keep in mind that if you lower the retraction distance, it can cause some strings to appear on the print, those can be easily removed with cutting pliers or a scalpel.

TPU also needs to be printed as slow as possible. If you force it through the nozzle at high speeds, it will get trapped in the bowden tube and cause a clog. The recommended speed for TPU is around 25mm/s.

- Configuring all the print speeds into the same value (wall speed, infill speed, etc) helps to print correctly the TPU 98A and softer TPUs, avoiding clogs or underextrusion issues.

Tighten the extruder motor thumbscrews to the max setting to ensure a good grip on the filament.

Tip 3: Improving the stability

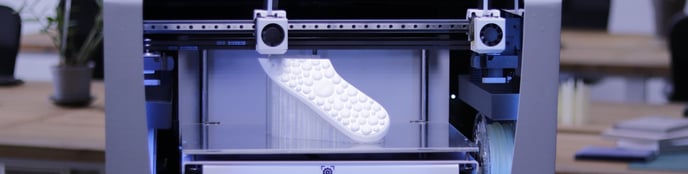

Being a soft and flexible material, TPU can lead to failed prints because of the stability of the model itself. To ensure a stable print, is recommended to use 0.8mm or 1mm hotends for best results (they also help in clog prevention), as well as triangle structure supports.

You can also modulate the flexibility of your printed parts by adjusting the wall line count and infill percentage (Lower the infill percentage and line count, more flexible parts).

Conclusions

- Properly store the TPU to prevent it from absorbing moisture from the air and causing printing problems.

- Reduces the printing speed of the TPU to 25mm/s or less.

- Avoid retractions and reduce the retraction speed.

- Use 0.8 or 1mm hotends to ensure part stability during printing.

- Reduce the wall line count and the infill percentage for more flexible parts.