In this article you will learn some information to help you master PVA

Note: This article contains advanced information regarding PVA. The default settings for our BCN3D PVA have been tailored for good quality and reliable results, and are fully tested by our laboratory. These tips complement those settings to ensure the best quality in printing with PVA.

PVA (Polyvinyl Acetate) is a material widely used in 3D printing as a support material for its ability to dissolve in water. This makes the material quite different from the rest, but there are some considerations to take into account in order to print with this filament. In this article, we will share some tips and tricks that we usually do in our day-to-day printing at BCN3D.

Tip: Check this material compatibility chart below, it will help you choose the materials that fit best with PVA:

Store it well

PVA is highly hygroscopic, which means it absorbs a lot of moisture from the environment, and quite quickly. When this happens, the PVA polymeric chains break down as the material heats up, making it granulous and not smooth. This can cause clogging and various printing quality issues.

If you want to prevent this from happening and know a bit more about this phenomenon, take a look at our guide on how to solve this common issue:

Printing issues related to humid filament

This filament is quite sensitive to UV radiation, and it will degrade if it's exposed to natural light for a fairly short period of time. Make sure to store the PVA spools in a dry, dark place, such as the Smart Cabinet.

Set supports properly

As said before, PVA is used as a support material, but there are some settings you should take into account to guarantee having the best overhang quality.

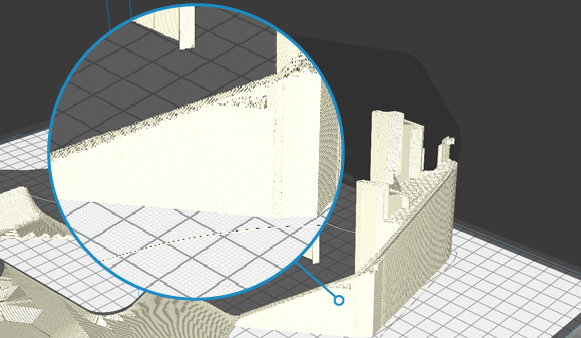

Ensure a good contact surface so the overhang is well supported on the actual PVA supports. A support interface will create a denser support structure under the overhang. Also set the support Z distance to 0mm, so the printed material is well stuck on the PVA.

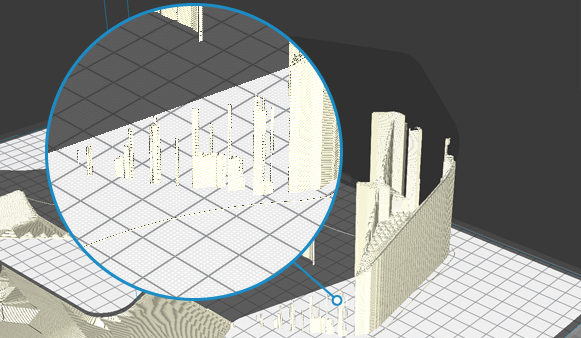

Avoid printing thin towers with PVA, this material needs to be printed in dense support structures. Setting a Support Density of 50% will do the trick and keep the print stable for larger supported areas.

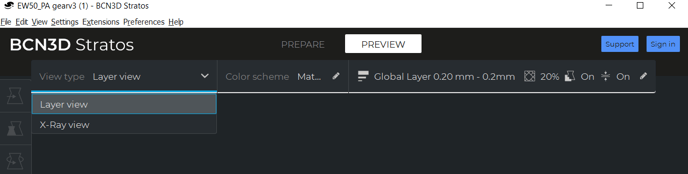

Tip: You can access this view by selecting Layer View on the View tab located at the top right corner of the screen after slicing the model.

If the overhang you need to support is narrow, you can play around with the settings to have a better support structure:

Support Overhang Angle: for better quality overhangs, they should be supported even if the angle between them and the build plate is printable, for maximum quality, set this parameter closest to 0 degrees

Support Horizontal Expansion: This setting extends the support structure, making it more stable. Raise it up to have more solid supports. Values around 10mm should work great.

If you want to save print time and material, you can choose the supports to be printed with the main print material, and the support interface printed with PVA. This will also prevent clogging issues. Here's how to set this up:

The less you use it, the better

This filament crystallizes when exposed to high temperatures for extended lengths of time, this clogs the nozzle and can ruin your print. You should pay special attention to the standby temperature and the time that PVA remains idle and hot without being extruded.

Setting a standby temperature below 150ºC and enabling a prime tower will prevent this from happening, by decreasing the speed at which the PVA crystallizes and purging out any crystallized PVA that may have formed while the printhead was idle.

After the print job, unload the PVA and store it in a dry, dark place, and clean the hotend immediately.

How to clean the hotend (BCN3D Epsilon)

How to clean the hotend (BCN3D Sigmax)

How to clean the hotend (BCN3D Sigma)

How to effectively dissolve it

Once you have a finished print, you'll need to remove the support material. Take out all the PVA you can by hand or with the help of pliers and dunk the print in warm water to reduce the dissolving time.

Forum Community

Need more tips? Check out our forum community for more info about this.

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done.

Maintenance Plan (Epsilon Series)

Maintenance Plan (Sigma Series)

Maintenance Plan (BCN3D Sigmax)

Maintenance Plan (BCN3D Sigma)

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |