In this article, you will learn information to help you master PAHT CF15. This carbon fiber material is easy to print but is necessary to take care of your filament to get well printed and strong parts

Note: This article contains advanced information regarding BCN3D PAHT CF15. The default settings for our BCN3D PAHT CF15 have been tailored for good quality and reliable results, and are fully tested by our laboratory. These tips complement those settings to ensure the best quality in printing with PAHT CF15.

1. PAHT CF15 introduction

PAHT CF15 (High-Temperature Polyamide reinforced with Carbon Fiber) is a composite filament that is stronger and stiffer than regular PA, it can withstand high operative temperatures, and it is very resistant to bending and shear force. This makes the filament suitable to print end-use parts that work under high stress.

This filament is quite easy to print and behaves quite well, however, there are some tips that will help you refine your results. Here are some tips that will help you in printing PAHT CF15.

Remember to check the material compatibility in case you are going to print parts that need to be manufactured with PAHT CF15 and another 3D printing filament.

2. Tips to improve PAHT CF15 printing

Tip 1: Store it well

PAHT CF15 is highly hygroscopic, which means it absorbs a lot of moisture from the environment, and quite quickly. When this happens, the PAHT CF15 polymeric chains break down as the material heats up, making it foamy and not smooth. This can cause clogging and various printing quality issues related to the part's strength, as shown in the next picture.

As an added tip, for longer print jobs, stuff some silica desiccant sachets inside the PAHT CF15 spool to prevent it from absorbing moisture.

As an added tip, for longer print jobs, stuff some silica desiccant sachets inside the PAHT CF15 spool to prevent it from absorbing moisture.

Make sure to properly store PAHT CF15 spools in a dry and dark place, such as the BCN3D Smart Cabinet or a closet.

Tip 2: Dry your filament

As the PAHT CF15 is hygroscopic, is highly recommended to dry the filament before print. Drying the filament keeps all the mechanical properties of this material and ensures a smooth surface on the printed part. Also, you can dry your printed parts in case you prepare a batch of them before installing or using the parts.

- Note: To dry the PAHT CF15 is recommended dry it in an oven or desiccant machine for 8 hours at 70ºC.

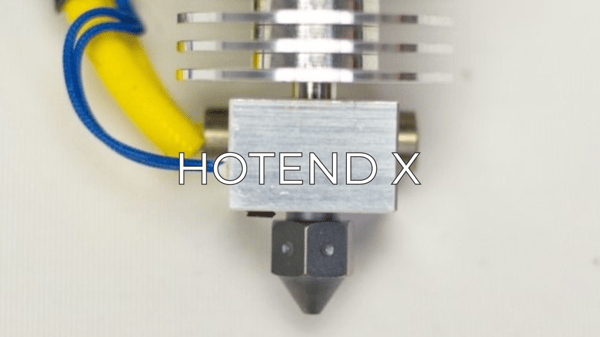

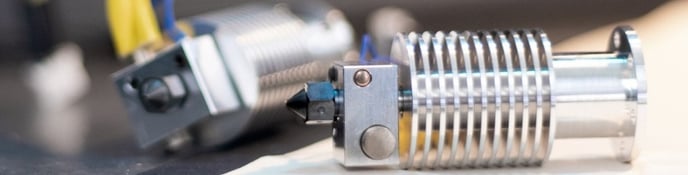

Tip 3: Use the correct hotend for an abrasive material

PAHT CF15 has Carbon Fiber in it, and it is quite abrasive. It is recommended to print it with our Hotend X, otherwise, it will wear out the regular hotends making them unusable in short time. The hotend X is prepared to ensure the good flow of the PAHT CF15, reducing the friction with the internal walls of the hotend and allowing to get a smooth finish in the printed part.

Tip 4: Autotune your hotends before print

The PAHT CF15 is printed at 280ºC, being necessary to perform an autotune process before printing, in order to improve the temperature control of the printer. To perform an autotune you can follow this process:

- Load the PAHT CF15 in your hotend X

- Go to the menu Utilities, Maintenance, Autotune hotends

- Wait until the process is completed

- Note: Is not necessary to perform an autotune before each print, however, is recommended to do this process each time that you change the material or one time per week.

Tip 5: Make it stick

PAHT doesn't need any special considerations regarding adhesion, you can simply print it with a clean build plate or with regular Magigoo with no risk of warping, as long as the printing surface is well calibrated.

Using the Magigoo in your prints helps to remove easily the parts and protects the printing surface from damage. Is recommended clean the printing surface and apply the Magigoo with the surface cold.

Using the Magigoo in your prints helps to remove easily the parts and protects the printing surface from damage. Is recommended clean the printing surface and apply the Magigoo with the surface cold.

After printing PAHT CF15, is necessary to wait until the surface is cold in order to safely remove the parts.

Tip 6: Postprocessing PAHT CF15

If you need to post-process your print with PAHT, like removing blobs or strings, you can use a scalpel, they should come off quite easily.

If you intend to sand down or polish your PAHT CF15 part, you should use safety glasses and an FFP3 facemask to prevent particles of the material from entering your eyes or lungs.

Priming and coating the PAHT parts, protect them from the humidity avoiding the necessity to dry the printed parts. Also, the coats can be used to smooth the surface after sanding o polishing the models.

Priming and coating the PAHT parts, protect them from the humidity avoiding the necessity to dry the printed parts. Also, the coats can be used to smooth the surface after sanding o polishing the models.

Conclusions

- Properly store the PAHT CF15 to prevent it from absorbing moisture from the air and causing printing problems.

- Perform an autotune to ensure that your hotend will keep stable the temperature at 280ºC.

- Dry your filament and your printed parts in case you don't have used them for a long time.

- In case you sand or polish your printed parts of PAHT, is necessary to wear safety glasses, facemask, and gloves. The PAHT emits small particles that can harm the eyes and the respiratory system.