Thanks to the Dual print mode is possible to print with soluble support materials, but it increases the printing time and the cost of the print job. In this article, you will find some tips to save some time and the material used

Why is necessary to optimize the usage of water-soluble materials?

This optimization consists in enabling the Support interface to reduce the amount of soluble material used, the number of tool changes, and in consequence the print time.

- This is an extension of the learning article The best way to optimize the use of PVA for 3D printing

Feel free to visit the articles related to the water-soluble material in the BCN3D portfolio.

How to set up the PVA or BVOH Support Interface

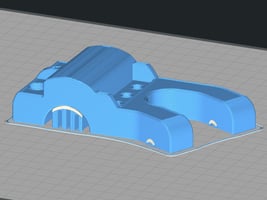

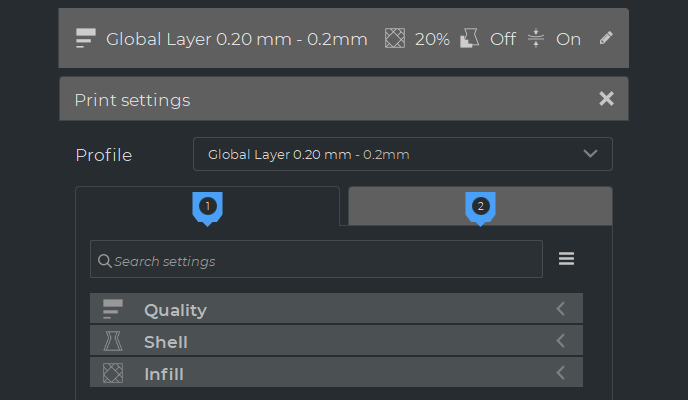

The support interface is a BCN3D Stratos setting that creates a denser pattern on the top and bottom of the supports to improve the surface quality of the parts that are in contact with the supports.

In BCN3D Stratos, you can set this top and bottom part to be printed by another extruder. This means we can print only the interface in PVA or BVOH, while leaving the rest to be printed with the main filament. To do so, follow these steps:

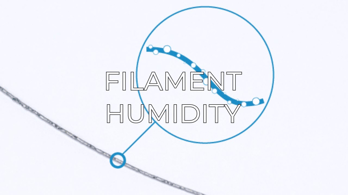

1. In BCN3D Stratos, go to Custom settings

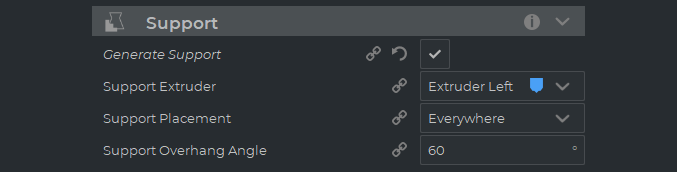

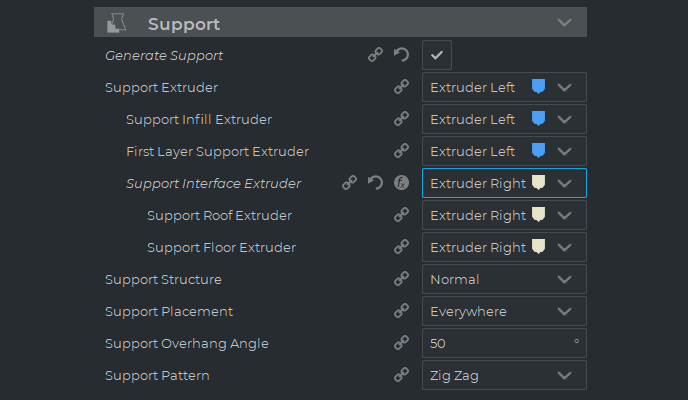

2. Open the Support tab and click Generate Support

If you don't find the support interface settings, like in the picture above, you should configure your setting visibility:

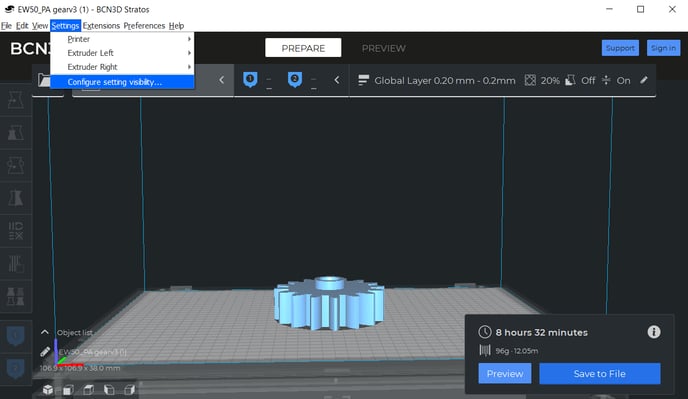

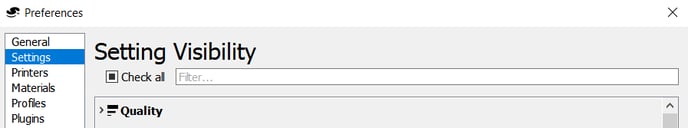

- Go to Settings/Configure setting visibility

- Click the "Check All" box

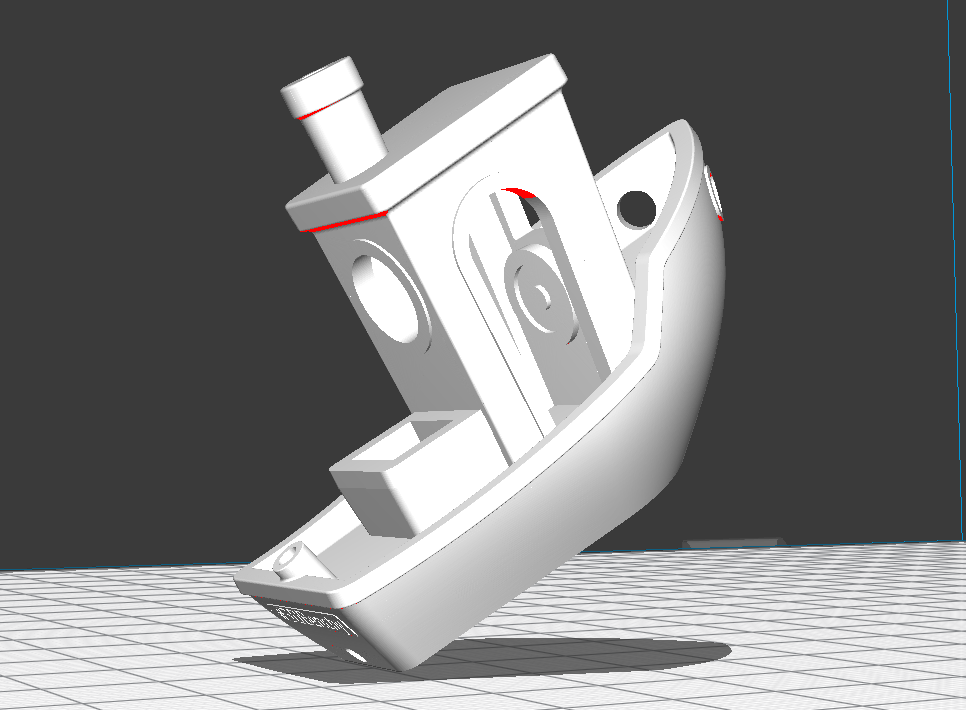

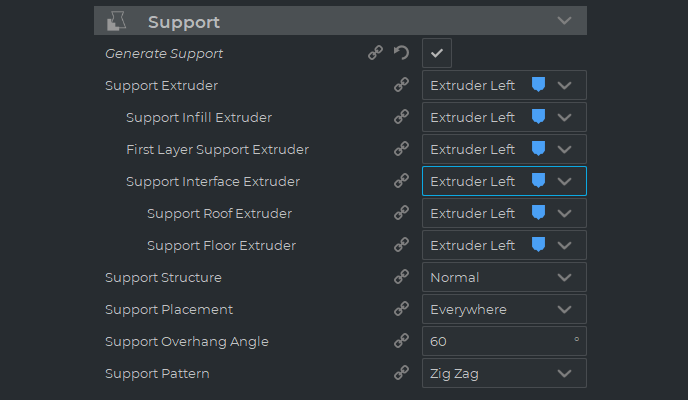

3. With the setting visibility properly configured, go back to the support tab and locate the Support Interface Extruder setting

4. Set up the extruder with PVA or BVOH as the support interface extruder

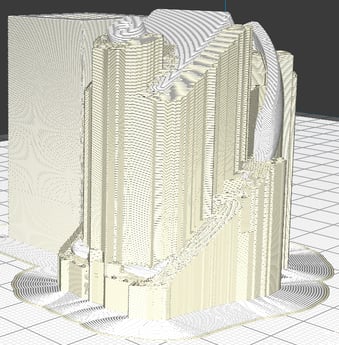

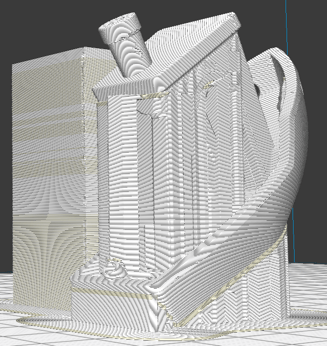

PVA Support Interface vs Traditional PVA Supports

This section will show a practical application of the Support Interface and its comparison with the standard PVA supports. Make sure to check this article to learn a bit more about this subject: The best way to optimize the use of PVA for 3D printing

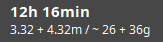

As observed above, the printing time is cut by more than 4 hours. The amount of PVA is also reduced, this will need to be dissolved. The size of the benchy is the same.

Conclusions

- Enabling the support interface saves material and time.

- Reducing the support material usage helps to avoid common problems related to water-soluble materials like clogs.

- This solution allows getting an amazing surface finish thanks to the soluble material but uses less material in the whole structure.

- If you want an even lower print time, you can disable the prime tower.

- Remember that disabling the prime tower can lower the quality of the part you want to print.

- After using water-soluble materials, store them in an airtight container or the BCN3D Smart Cabinet to keep them dry and ready to be used in another print.