How to design for 3D printing

In this article, you will find different design guides for 3D printing related to the geometry, the application, dimensional accuracy, dual printing, and tips to split models

The big achievement of additive manufacturing is the creation of parts and geometries that by traditional manufacturing methods would be almost impossible to do, this method allows to make an infinity of models with complicated shapes to perform a certain function.

To ensure that the model will be printed correctly is necessary to design the 3D models knowing the physical limitations of the materials and the technology. In the following guides, you will find design guides to archive this goal.

1. Tips to designing 3D printable models

In this article, you will find general tips to design for 3D printing depending on the material and the hotend that you will use. Applying these design tips will improve the printing results

2. Dimensional accuracy tips

It is not only the esthetic that matters, the dimensions are also very relevant. Learn how to improve the dimensional accuracy of your 3D prints from the design to the maintenance of the printer0

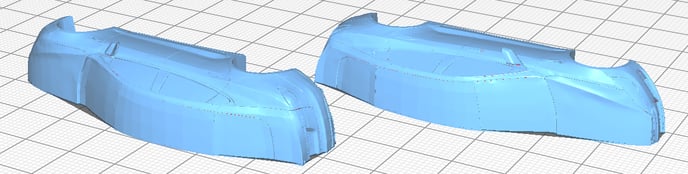

3. Split the model in multiple parts

Is your design too big and doesn't fit? It's time to cut it. Splitting the 3D models helps to avoid the support structures usage and depending on the model could save time. Also, this guide will show you how to modify the parts to be joined easily.

4. Design models for dual printing

Thanks to the IDEX technology is possible to print models with many colors or materials, in this article, you will find tricks to design the model to use the Dual Mode to do only one print with many materials and colors

| Send us your comments about this article |

|

||