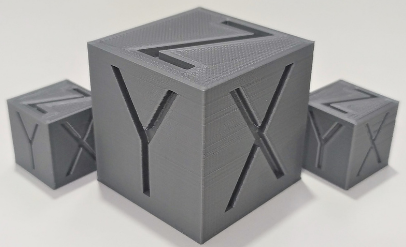

The design of the model, the shrinkage ratio of the material, and the maintenance of the printer could affect the dimensional accuracy. In this article, you will learn how to improve the dimensional quality of your prints

What can affect the dimensional accuracy of 3D models?

The accuracy of printed parts is of course very important, especially for projects that require an exact fit between other components.

There are a number of common causes that can affect the accuracy, such as under-extrusion or over-extrusion, filament properties, and the quality of the first layer. Additionally, the intricacy of the print model’s design can play a role in obtaining satisfactory results.

- We recommend measure 3 times the same part of the model in different positions to avoid measuring errors.

- Once you have measured the model, you can compare the quality with the common accuracy values for FDM machines:

In most cases, positive dimensional errors are better because you can fix them during the post-processing of the model.

How to improve the accuracy of the 3D models

After printing this test, you can continue to improve the accuracy of your 3D printed models by implementing the following steps.

Tip 1. Check the model units

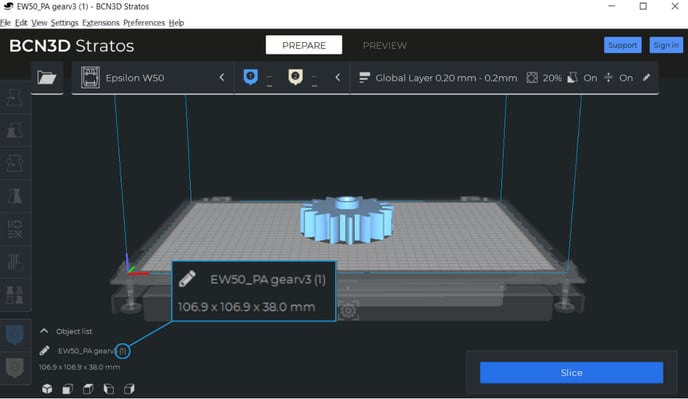

If your slicing software uses one unit and the model is designed in another, you will notice an obvious difference between the two models. Although this issue can go unnoticed, it can cause a lot of problems when measuring 3D models.

Therefore, make sure that you are using the same unit to design and slice your model.

- Note: The BCN3D Stratos works with millimeters (mm)

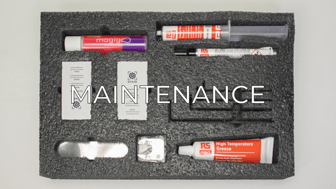

Tip 2. Clean and lubricate the axis

A common problem with accuracy is a lack of maintenance, specifically the cleaning and lubrication of the axis. If the printing head, carriage, and printing platform have problems moving smoothly, the accuracy is affected.

We recommend carrying out maintenance on the printer every week and protecting the printer from the dust and leftovers of filament in the linear guides and the Z-axis structure.

- Click on the picture corresponding to your printer to learn clean and lubricate the axes:

- Note: Lubricating the pulley's shaft and the bearing pillows helps a lot, you only need to add some mechanical oil over these components.

Tip 3. Adjust belt tension

The movement transmission is of the utmost importance when you want accurate measures. If the belts are loose or too tight, the movement could result in dimensional inaccuracies.

- Click on the picture corresponding to your printer to learn how to adjust the belts:

- Note: Our guides have a printable tool for checking belt tension.

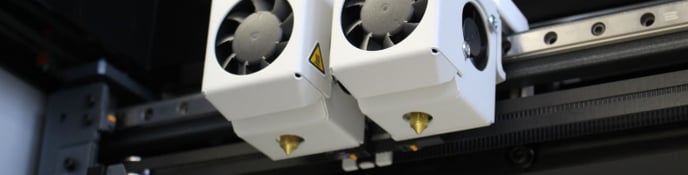

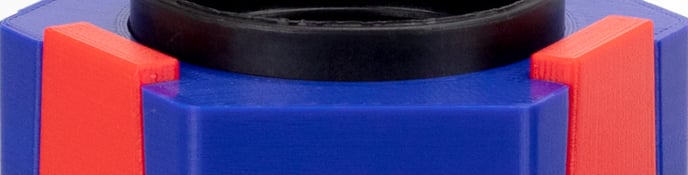

Tip 4. Change the hotend for a small one

Different hotend sizes produce different results for the same model. For example, hotends with big diameters need less time to complete the print but sometimes lose accuracy on details.

In this article, you can find more information about the difference between hotend sizes and how to choose them according to your needs: How to choose the right hotend size for each 3D printing application

Tip 5. Reduce the print temperature and flow rate

In order to further increase the accuracy of your print, you can lower the print temperature by 5ºC and the flow by 5%, until the excess of material disappears.

Be cautious when doing so, as this can lead to under-extrusion and clogging in the hotend. The best way of performing this adjustment is to use small steps on repeated prints.

Print speed

The speed at which you print also affects accuracy. High speeds can cause a tiny layer shifting in some areas of the model, which can be eliminated by reducing the speed by 50%.

If you want to print faster than the recommended speed from our BCN3D Stratos profile, you can modify the infill pattern and density, optimize the support structures and adjust the wall and infill speed.

Cooling between layers

When the nozzle is continuously moving in the same area, this can cause an excess of temperature that softens the material and creates small irregularities, leading to accuracy issues.

This can happen when printing thin pieces that are also tall e.g. a small diameter cylinder. Another typical deformation occurs in inclined cantilevers: the material which is still-hot is deformed when suspended in the air until it solidifies.

These problems can be solved by making adjustments to the layer fan. If you notice that the walls of your model are irregular, similar to over-extrusion, check the cooling configuration of your profile and try to increase the fan speed and minimum layer time.

First layer's quality

.png?width=688&name=primera%20capa%20Cropped%20(1).png)

The first layer is the most important layer of a print, as the rest of the piece will be built on top of it.

One problem that can arise in the first layer is called "elephant's foot"; this issue is caused by a bad calibration that squishes the first layer, making it spread out more horizontally compared to the rest of the model.

Is recommended to measure the model at different heights to avoid the error that adds the "Elephant's foot" and recalibrate the printer to increase the separation between the nozzle and the printing surface.

Constant dimensional error

The BCN3D Stratos offers the option to offset the edges of your model. This setting is called the "Horizontal Expansion", which works perfectly when the measurement error is constant. For example, if you check the size of your model and you notice that it is 0.2mm bigger in the X and Y directions, you can apply -0.2mm of horizontal expansion to remove this difference.

- Also, this option could be used to compensate the elephant foot error on the first layer and the size of the holes in the XY plane.

Designing to compensate for the tolerance

Although these aforementioned steps can help you to improve the dimensional accuracy of your 3D models, we cannot expect perfect accuracy from the printed versions everytime.

Subsequently, it is important to take this inaccuracy into account when designing your own models. For example, if you are creating a hole in a model to fit another part into and your printer consistently makes the error of holes being 0.1mm too small, you should design the hole 0.1mm bigger.

Conclusions

- Check the lubrication and the belt's tension of your printer to avoid any mechanical issue that can cause the inaccuracy

- Changing the hotend by a small one, reducing the temperature and the print speed could help to make more dimensional accurate the models.

- Check that the first layer is correctly printed at the beginning of the print to avoid Elephant's foot

- You can compensate some inaccuracies using the Horizontal Expansion parameters.

- Keep in mind that designing the models taking into account the contraction of the material and the tolerance of the 3D print, could help you to get accurate models

- If you still experience accuracy issues, get in contact with our support team by filling this form.