Note: The oozing can also be related to the humidity of the filament, make sure to dry and store the filament correctly before and after use.

In this post, we will discuss the print sequence parameter of BCN3D Cura, the possibilities it provides, and when and how to use it in a correct and meaningful way so that our printing platforms always generate optimum quality.

Getting started

The print sequence parameter can be found in special modes in the print setup dropdown in custom mode of our slicer BCN3D Cura. With this option, you can choose whether to print all the models at once, or to wait until you finish a model before moving on to the next one. This parameter therefore consists of a drop-down menu with two possible options: all at once or one at a time.

.png?width=300&name=all-at-once%20Cropped%20(1).png)

Why is it necessary?

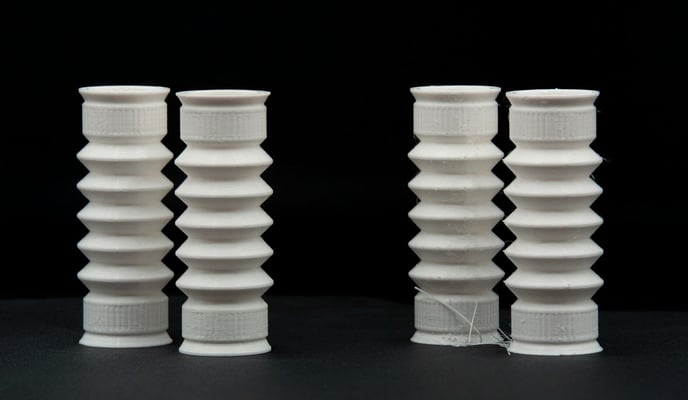

The essential difference between using one option or the other lies in the simple fact of whether we prefer to print them all at once or one at a time. When printing parts all at the same time, the cooling time of the layers is longer. The more pieces there are on the platform, the weaker the bond will be, as well as generated shrinkage between pieces. On the other hand, when printing one at a time, the layer cooling time is shorter, therefore providing stronger welding between layers and avoiding shrinking and threads between pieces.

The right decision for your application will depend on your material of choice. By default, the all at once option is activated, so it is important to know when to change it to printing one at a time i.e. sequential printing.

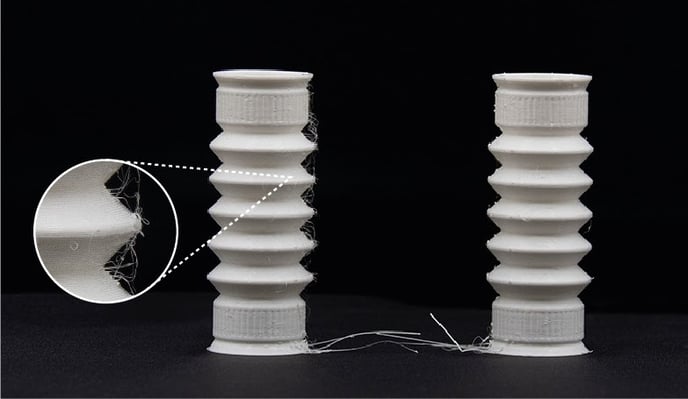

The one at a time option is the correct choice when the material being used generates a lot of oozing, which are these threads that can be found between parts of the piece due to the material not retracting well.

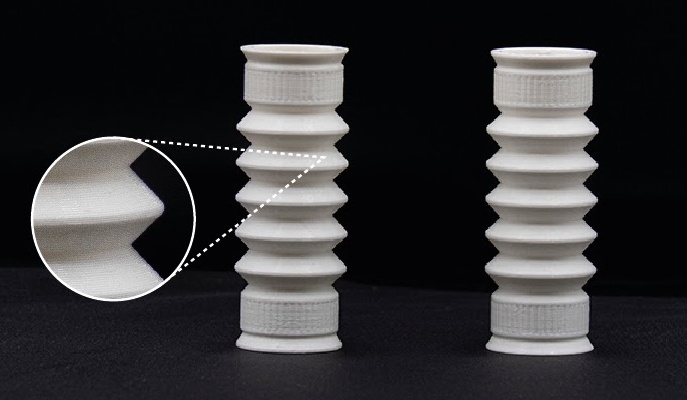

In general, the material that causes the most oozing is TPU. Therefore, sequential printing is mandatory in order to generate good quality parts in flexible materials. If we don't take this into account when we generate the G-code, we will find ourselves with a printing platform with threads between all the parts we have placed in the printing area.

On the other hand, if we instead decide to print these pieces one by one, we will avoid the threads between pieces and these subsequent defective bumps on the surface of our pieces.

Things to keep in mind

When using the one at a time mode, bear in mind that this only works if all the models are separated in such a way that the print head can move without colliding with the already printed models.

To help us to know what distance to keep between the models, the BCN3D Cura software will create a shadow around them; this shaded area represents the limits of where the head will reach while printing the part.

The one at a time command will start printing the pieces at the front first and then, little by little, it will go backwards to print the rest of the pieces.

In summation, should you be using a fitting material, implementing the use of sequential printing can be extremely beneficial for avoiding oozing between parts and the formation of imperfections on their surfaces.

Forum community

Do you need more advice? Check out our forum community.

It is important to keep your printer in good condition to get the most out of it. In this chart, you will find a list of maintenance procedures and the frequency with which they should be performed.

Maintenance plan (BCN3D Sigma)

Maintenance plan (BCN3D Sigmax)

Maintenance plan (Epsilon series)

Maintenance plan (Sigma series)

![]() Take your e-waste to a certified recycler. Check how we do it at BCN3D

Take your e-waste to a certified recycler. Check how we do it at BCN3D

|

You can help us improve BCN3D Knowledge Base. If you think we are forgetting a step or you find an error, please use this form and let us know. :) Form |