Print mechanisms totally assembled is one of the things that you can do with 3D printing. In this article, you will find what you need to be able to design and print models that have moving parts.

Before the appearance of 3D printers, prototypes and final products had to be manufactured using subtractive technologies, wherein the case of objects with mobile elements had to be manufactured separately and then assembled. With 3D printing, this is no longer a necessity thanks to the ease of creating mechanisms that have free spaces between parts, which allow their movement.

- The following design tips complement the Tips to designing 3D printable models to get moving parts.

Table of contents

- Space between pieces and tolerances

- Supports for the mechanism

- Improve mobility with post-processing

Space between pieces and tolerances

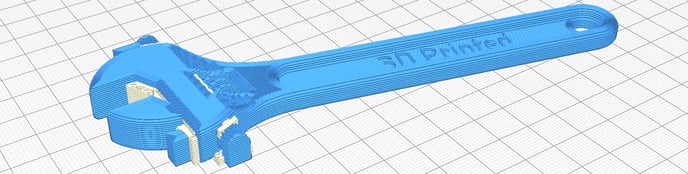

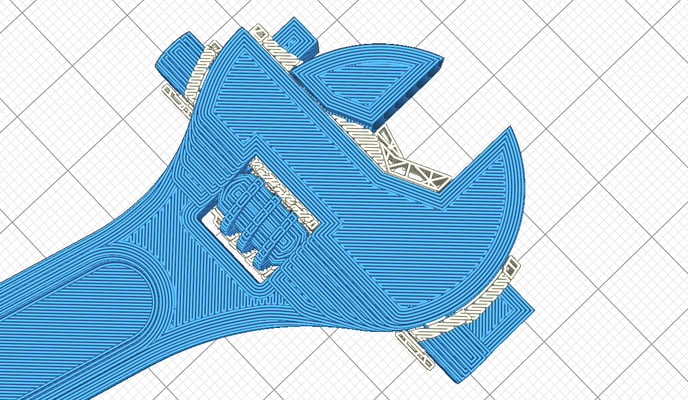

In 3D printing, objects are manufactured layer by layer so if the models were designed being in perfect contact, it would cause the extruder to fuse the pieces, creating a single object and preventing movement.

The best way to prevent the pieces from joining is by leaving a separation between the models when designing them, is recommended to leave a separation twice the layer height with which the 3D model will be printed. This space will be small enough not to be visible to the eye but useful for printing soluble supports in the area.

.png?width=688&name=wrench-space-between-parts-designing-3d-printable-models%20Cropped%20(1).png)

In the case of designing and printing the parts separately to later be assembled, the printing tolerances must be taken into account. Leaving a margin between 0.1mm to 0.3mm is usually enough so that the pieces have looseness, can fit together, and move.

Supports for the mechanism

Since the mechanism will have empty spaces between the pieces, in some cases it may be necessary to use supports to print the assembly.

The optimal materials to support moving parts are water-soluble due to the following advantages: they are removed by dissolving in water and they do not leave traces of materials that could obstruct movement between parts.

It is important that the piece has the necessary spaces and holes so that the water can flow between the parts and dissolve all the supports.

The supports of the same material of the piece are only recommended when the parts of the mechanism are printed separately since in case there are remains of material on the piece they can be post-processed.

Improve movility with post-processing

The smoothness of the movement of the mechanism depends on the surface finish of the parts, so in some cases, it will be necessary to carry out post-processing.

However, post-processing tasks can be complicated to perform depending on the assembly, since there may be a lack of space to insert and use the necessary tools.

If you have enough space or can disassemble the assembly, sand the surfaces of the model to be desired finish and mobility. This is quite beneficial when the layer height very wide, as this is the area where the greatest amount of friction will accumulate.