In this article we are going to explain the differences between BCN3D water-soluble materials

%20Cropped.jpg?width=688&name=IMG_20210205_115546%20(2)%20Cropped.jpg)

BCN3D has its own material portfolio that includes two different options for soluble supports, PVA and BVOH.

PVA or polyvinyl acetate is the most traditional option when it comes to soluble supports. It is widely known as the first soluble material in the 3D printing industry. However, with this material´s regular printing issues and the addition of new 3D printing materials, there has been a drive in the creation of new soluble materials that adjust more to these classic problems. One of these is BVOH, a copolymer of vinyl alcohol with features that make it compatible with many more materials print friendly way.

Solubility

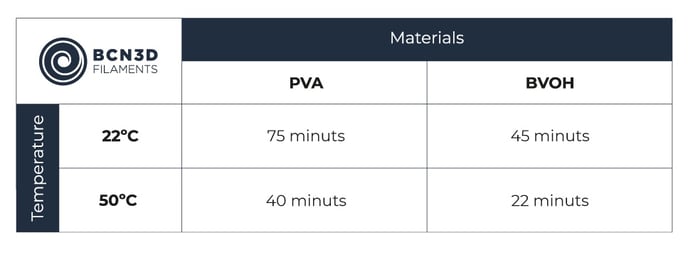

The most characteristic feature of these materials is the ability for them to dissolve in water, but the first difference between PVA and BVOH is that BVOH dissolves much quicker. The remains left in the print are also lower in BVOH.

You can check this time lapse of the dissolution time of both materials in water.

This image shows the time comparison and how the water temperature affects the dissolution time.

Compatibility with other materials

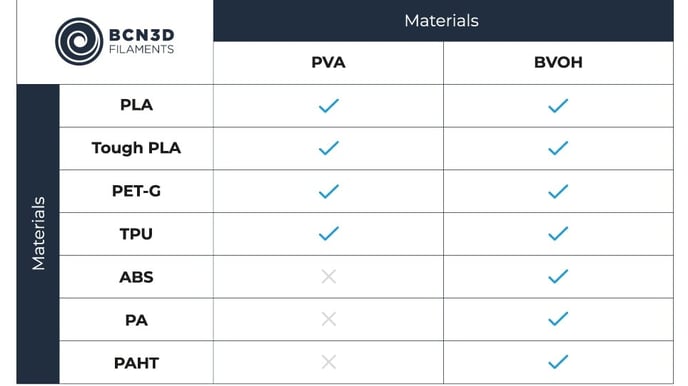

It is true that PVA is one of the most common materials in 3D printing. Nonetheless, this doesn't mean compatibility with other commonly used materials. ABS, PET-G, and Nylon are examples of materials with which PVA is not compatible. BVOH on the other hand is compatible with almost all BCN3D filaments.

You can check the differences of compatibility between both materials in the chart below:

Even though the compatibility is possible, the adherence between PVA and other materials is quite difficult.

Humidity absorbing capacity and degradation

All water-soluble materials have a greater capacity for absorbing humidity and degradation with time. Depending on the material, the speed can increase drastically.

PVA has a greater humidity absorbing capacity because of its thermal properties. It degrades easily so it's not recommended for long printing times. BVOH also has a quick absorption speed but because it has an extreme high-temperature tolerance, it degrades less. Therefore, it can print for up to 2 days without any problems in closed models such as the Epsilon.

It's recommended drying both support materials initially to guarantee the best results and to avoid any kind of issue related to humidity. Find out more on this article: Printing issues related to humid filaments

The Smart Cabinet can be a solution to this significant support material issue. It ensures the optimal temperature and humidity conditions for long printing times.

Printing difficulties

Each material has its own complications when printing, but it is well known that PVA is one of the most difficult to use.

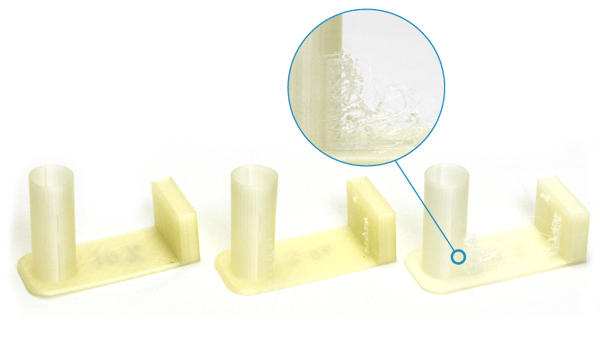

PVA has three main problems: it generates a lot of stringing, it is easy for it to underextrude in the effort to reduce stringing, and it blocks hotends very easily. This makes printing PVA a skill. Every printing parameter must be precise whether the amount of material being used, the printing time, even the humidity levels.

In this aspect the BVOH outperforms the PVA. The possibility of stringing is lower, therefore the extrusion can be more continuous by not having to touch parameters to solve this fault and ensuring that the hotends do not block.

In the following articles you can find tips and tricks to print both materials:

You can buy BVOH and PVA in our shop: BCN3D BVOH and BCN3D PVA

Community forum

Need more advice? Check out our community forum for more information like this one.

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done.

Maintenance plan (Epsilon Series)

Maintenance plan (Sigma Series)

Maintenance plan (BCN3D Sigmax)

Maintenance plan (BCN3D Sigma)

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |