Learn how to Plan your Print Appropriately to Obtain the Desired Results

When you configure a g-code, it is necessary to pay attention to the orientation of the model in order to simplify the printing process or improve the resistance of the printed part to certain stresses.

In this article, we offer you different tips to plan the piece according to different needs.

Content table

Guide based on efforts

The best orientation to achieve the highest level of detail

Reduce or eliminate supports

Orientation Based on Efforts

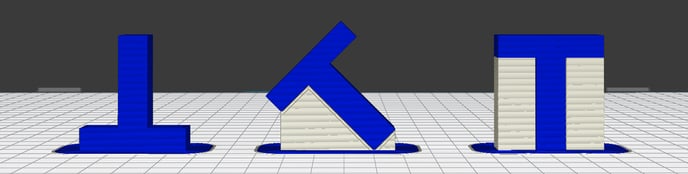

Due to the manufacturing method, not all the axes of the piece have the same resistance to certain types of efforts. Depending on the utility of the printed object, it must have a certain specific orientation

For compression effort, the most resistant axis is the Z. As the layers are stacked, the resistance of crushing is very high.

However, the Z-axis is not very resistant to tensile efforts. For these, the best orientation is one of the X and Y axes. Also, the filament welds are longer, which causes the force to be distributed correctly.

If the piece must be subjected to traction or compression, the ideal would be to choose an inclined plane focused on the trajectories of these forces. The angle will determine how the forces are distributed in the piece, the balance point being 45º

The Best Way to Achieve the Highest Level of Detail

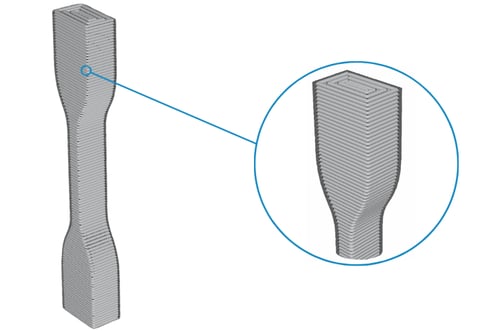

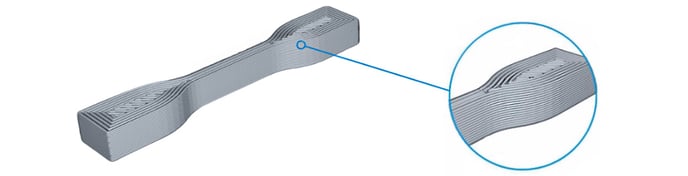

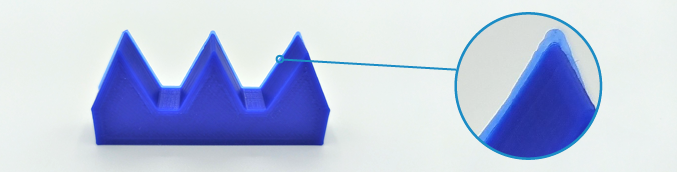

Details are influenced by the resolution or level of detail that can be achieved on each axis.

On the X and Y axis, the resolution is determined by the thickness of the printed lines that make up the layer. This value is commonly the diameter of the hotend nozzle.

For the Z-axis, the resolution is given by the layer height, allowing for a better finish, since the fine details will be generated better by the laminator.

For this reason, it is preferable that the details are oriented in the direction of the Z-axis.

Tip: While the diameter of the hotend is smaller, the level of detail will be higher

Reduce or Eliminate Supports

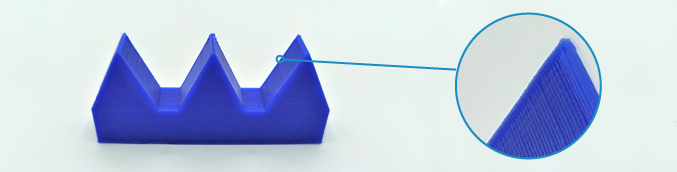

Depending on the geometry and orientation, a part may need more or less supports to be printed. This will affect material consumption and printing time. Here are some tips to use the least amount of supports:

- In models with several flat faces that can serve as a base, you must choose the one with the least number of overhangs.

- For parts without a defined base, the flatten option in the BCN3D Stratos menu allows planning the model in a manner that has the greatest amount of support points with the printing surface.

- Disabling the "adjust rotation" option in the menu allows you to rotate the model freely.

Forum community

Need more tips? Check out our forum community for help.

It's important to keep your printer in good shape to make the most out of it. In this chart, you can find a list of the extruder maintenance procedures and how frequently these should be done.

Maintenance Plan (Epsilon Series)

Maintenance Plan (Sigma Series)

Maintenance Plan (BCN3D Sigmax)

Maintenance Plan (BCN3D Sigma)

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.

|

You can help improve the BCN3D Knowledge Base. If you feel there are guides that we are missing or you found any error, please use this form to report it. Report form :) |