Check out this article to avoid first layer underextrusion issues.

What is Underextrusion?

Possible causes of underextrusion in the first layer

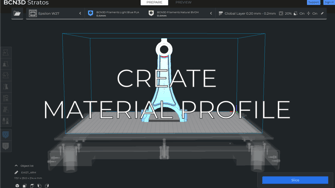

1. Enable the adhesion settings or increase the purge distance

One of the common causes of underextrusion in the first layer is that the hotend doesn't have prime correctly the material before printing the model. To avoid this is highly recommended to select a build plate adhesion type.

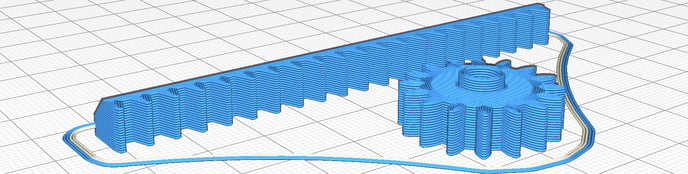

The build plate adhesion type allows choosing one of the 3 different adhesion supports that helps to prime the hotend before printing the model.

- If selecting a build plate adhesion type doesn't solve the problem, you can increase the start purge distance over 10mm.

2. Check if the hotend is clogged

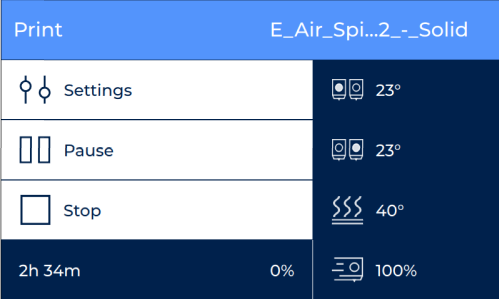

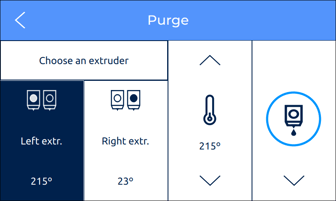

If under extrusion still is happening during the first layer, make sure that filament is actually coming out of the nozzle. To do so, stop the print job, go to the Utilities/Filament/Purge menu, preheat the hotend and check if filament is coming out.

- If the filament is not coming out when performing a purge check the following, you must have a general underextrusion issue.

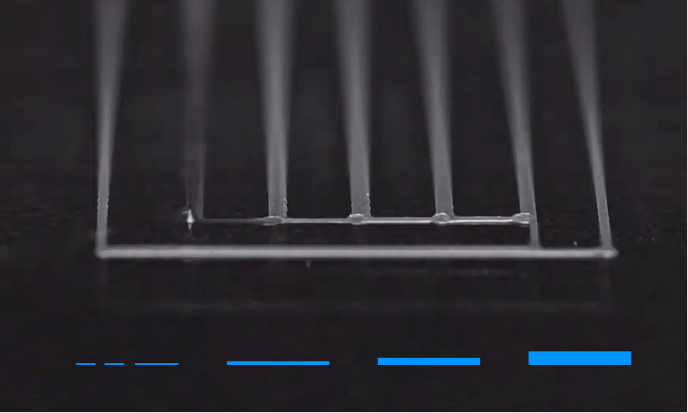

3. Calibrate correctly the printer

If filament is coming out correctly, it’s possible that the Z axis is not properly calibrated and the filament is not coming out due to the hotend being too close to the glass.

In this case, you can calibrate the printer following the instructions in the attached article, making sure that Z axis is properly calibrated.

- Click on the picture of the model of your printer to learn more about how to calibrate the hotend in your printer:

- Click on the picture of the model of your printer to learn more about how to calibrate the printing surface in your printer:

/photoroom%20(15)%20Cropped.png?width=546&name=photoroom%20(15)%20Cropped.png)