How to Properly Configure and Print the Supports

| Remember that BCN3D Cura will not receive new software updates. Please download BCN3D Stratos our new slicer for improved performance. |

This article is part of our guide on how to perfect the brackets. If you want to know more about the process of perfecting the support structures or have missed any of the articles that make up this guide, visit the links below:

The way in which supports are generated and printed directly affects the surface finish of the piece, therefore it is necessary to take into account different aspects so the support structures are resistant and correctly adhere to the piece.

Table of contents

Improve the resistance of the support towers

How to remove supports in unwanted areas

Avoid support breakage during the printing

Improve the surface quality of the part

Note: To properly configure the supports, it is necessary to check the layer view after each adjustment.

Improving the resistance of the support towers

It is quite common for thin towers to be generated to hold very thin parts of the piece, however, they are not resistant and tend to break during the printing process.

To improve the strength of the towers, the following support configuration parameters can be adjusted:

Use towers: activating this parameter creates specialized towers to support small areas of the model. The thickness of the base can be modified to have thicker towers and the diameter varies as it reaches the top of the tower to form the roof the will hold the piece.

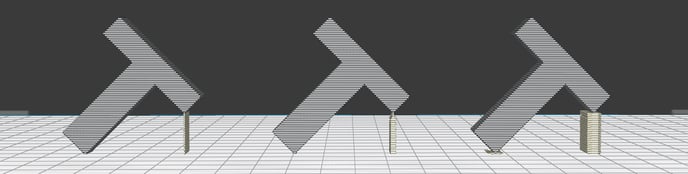

Horizontal expansion of the support: Increases the overall thickness of the support, allowing the tower to be thicker and stronger.

How to Remove Supports in Unwanted Areas

On some occasions, supports will be generated in areas that the part does not need support, such as small overhangs. To avoid this problem you can adjust the following parameter:

X/Y distance of the bracket: By increasing this distance, no supports are generated in overhangs that separate said distance from the part.

Support placement: If you want to remove all the supports that are generated on the surface of the model, you can change the support placement to "Only touching the print surface"

Avoiding Support Breakage during the Print

The supports have the thickness of the diameter of the hotend, so they are usually quite brittle and can break during the print. By modifying the pattern and other parameters, the robustness of the supports can be increased:

Support pattern: The grid and triangle patterns are quite resistant to tearing during the printing process. These patterns are only recommended to be printed on soluble material, as they are quite difficult to remove.

.png?width=252&name=support-print-speed%20Cropped%20(1).png)

Support printing speed: If the supports are printed too fast there is a risk of the structure breaking. By reducing the speed, the structure avoids vibrations or being damaged by the passage of the head.

Improving the Surface Quality of the Part

The quality of the contact surface depends on the Z distance from the backing pattern, the direction of the top and bottom lines of the perimeter, and the amount of material holding the base of the part. Modifying these parameters can improve the surface quality but complicate the process of extraction of the supports.

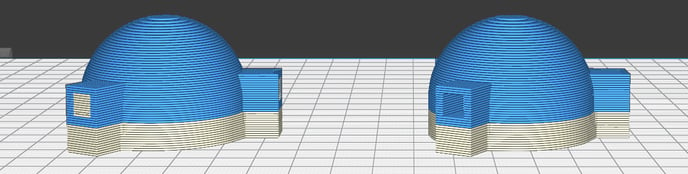

Support Z distance: Reducing the distance in the Z-axis between the support and the part prevents the filament of the first layers of the overhangs from hanging, however, the supports will be more difficult to remove. If you do not use soluble materials for supports, it is advisable to leave at least a distance equal to the layer height to remove it more easily.

Support pattern and top/bottom pattern: The patterns of the support and the perimeters influence how the piece of the supports is fastened, the ideal is that the patterns intersect as much as possible to better fasten the first layer.

Top/bottom Line directions: Changing the direction of the perimeter pattern helps to hold the bottom piece layer, as it allows the backing and perimeter patterns to better intersect.

Support density: The higher the density of the supports, the better the piece will hold and therefore the surface finish will improve.

Forum community

Do you need more advice? Check out our forum community.

It is important to keep your printer in good condition to get the most out of it. In this chart, you will find a list of maintenance procedures and the frequency with which they should be performed.

Maintenance plan (BCN3D Sigma)

Maintenance plan (BCN3D Sigmax)

Maintenance plan (Epsilon series)

Maintenance plan (Sigma series)

![]() Take your e-waste to a certified recycler. Check how we do it at BCN3D

Take your e-waste to a certified recycler. Check how we do it at BCN3D

RELATED ARTICLES |

|

|

|

You can help us improve BCN3D Knowledge Base. If you think we are forgetting a step or you find an error, please use this form and let us know. :) Form |