How to choose the Support Material

| Remember that BCN3D Cura will not receive new software updates. Please download BCN3D Stratos our new slicer for improved performance. |

This article is part of our guide on perfecting the brackets. If you want to know more about the process of perfecting the support structures or have missed any of the articles that make up this guide, visit the links below:

How to properly configure and print the supports

The first step before setting up the supports is to choose the material they will be made of. The most common options are water-soluble materials or the material of the piece itself, each one offers advantages and disadvantages when printing:

Table of contents:

Use soluble materials for the supports

Use the same material for the part and support

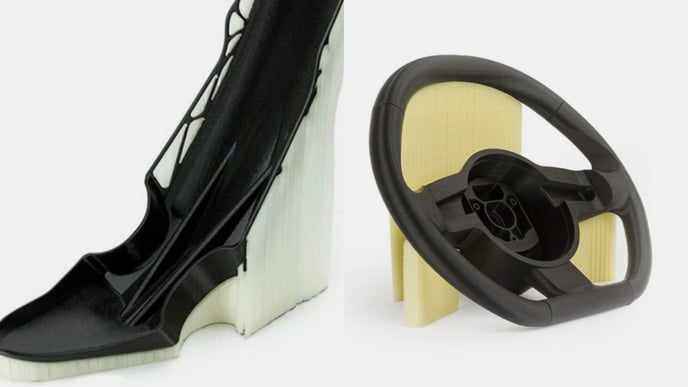

Using soluble materials for the supports

The unique characteristic of these materials is how easily they are removed from the printed piece since the only step required is to put the model in water and wait for the supports to dissolve.

At BCN3D we have BVOH and PVA, if you want to know more details about these materials you can visit the following articles:

Details to be considered

- Easily removed Immersing the piece in water and waiting for the supports to dissolve is all it takes. Use warm water to speed up the process.

- A good surface finish Thanks to the fact that the supports are easy to remove, they can be printed in direct contact with the part, which improves the surface finish of the overhangs.

- Ideal for complex geometries with a high level of detail.

- Check compatibility with your printing material: To find out which materials are compatible with soluble materials, click on the following article: Material combination.

- Must be stored correctly: Due to their properties of dissolving in water, they also tend to absorb a lot of moisture, so it is necessary to store the material correctly. In this article, you will learn the best ways to store your filaments: How to handle and storage BCN3D filament

Using the same material for the part and support

The option to use the same material for the entirety of the print helps simplify the printing process and save time.

Details to consider

- It is more difficult to remove the supports: Being that the supports are of the same material, they easily fuse to the piece and make the extraction process difficult.

- There is a possibility of damaging the part when removing the supports: In cases where the support is too attached to the part (and especially in weak areas of the model), the part could fracture or break if too much force is applied to remove the support.

- Need to post-process the part: It is usually necessary to sand the contact surface to remove filament residue or irregularities. To understand how to post-process your piece once printed, check out this guide Post-processing

- It is not recommended for models with complex geometries or large amounts of details.

Forum community

Do you need more advice? Check out our forum community.

It is important to keep your printer in good condition to get the most out of it. In this chart, you will find a list of maintenance procedures and the frequency with which they should be performed.

Maintenance plan (BCN3D Sigma)

Maintenance plan (BCN3D Sigmax)

Maintenance plan (Epsilon series)

Maintenance plan (Sigma series)

![]() Take your e-waste to a certified recycler. Check how we do it at BCN3D

Take your e-waste to a certified recycler. Check how we do it at BCN3D

RELATED ARTICLES |

|

|

|

You can help us improve BCN3D Knowledge Base. If you think we are forgetting a step or you find an error, please use this form and let us know. :) Form |