This is a continuation article of the How to fix Layer Shifting guide.

If you haven't read it, take a look at it first, you'll know why it happens and other ways to fix it. How to fix layer shifting.

Layer shifting in the Y axis is a printing issue where the layers of the object are misaligned on the Y axis direction. It is usually a mechanical problem but it also can be caused by a stepper driver malfunction or a bad configuration in BCN3D Stratos.

To solve this issue, follow in order the steps below.

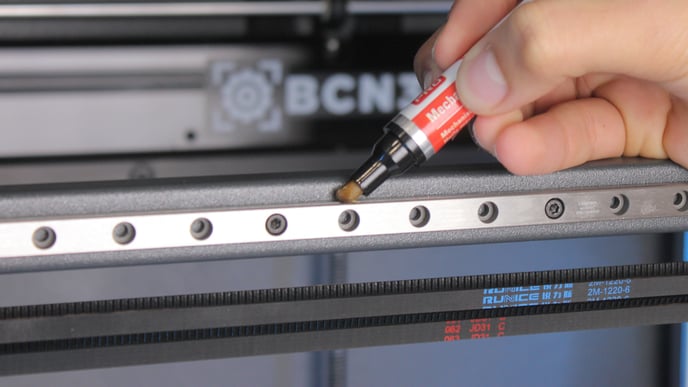

Cleaning and Lubrication

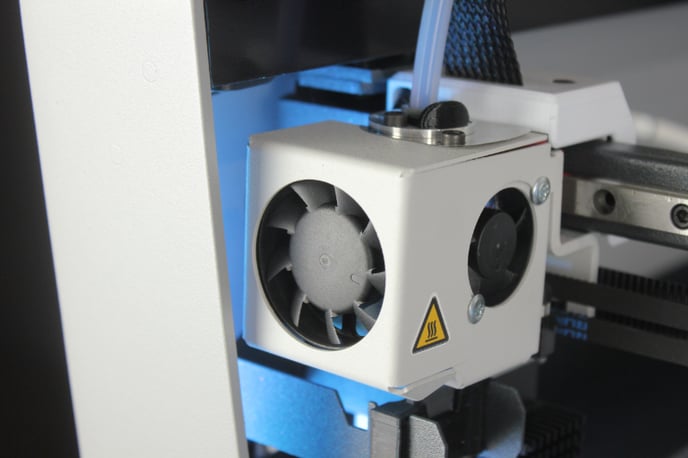

Clean the guiderail's surface with a clean piece of paper, and apply some lubricating oil while moving the X carriage forwards and backwards. Pay special attention on the ridges of the guiderail.

Note: you can purchase our maintenance kit on our website: Maintenance Kit BCN3D Epsilon

If you need more information about how to clean the axis, check out this guide: How to clean and lubricate the axes (Epsilon Series)

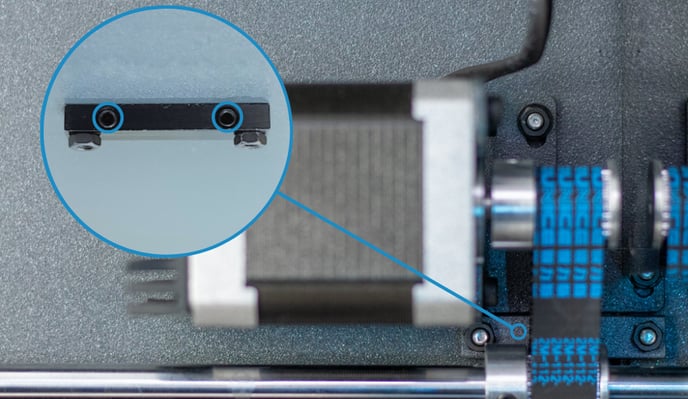

Adjusting Belts Tension

In order to adjust the belt tension, check this guide to receive more information:

How to adjust the tension of the belts (Epsilon Series)

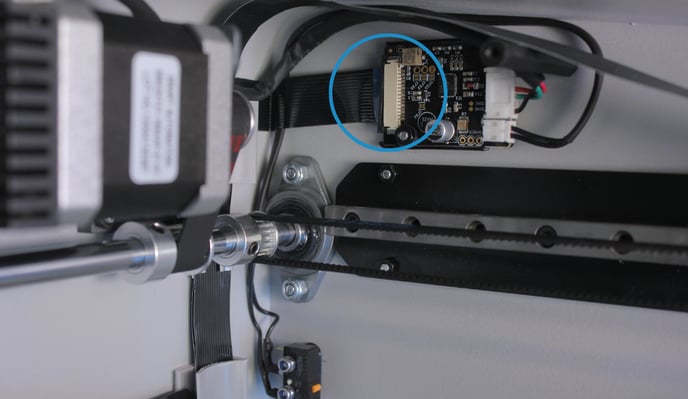

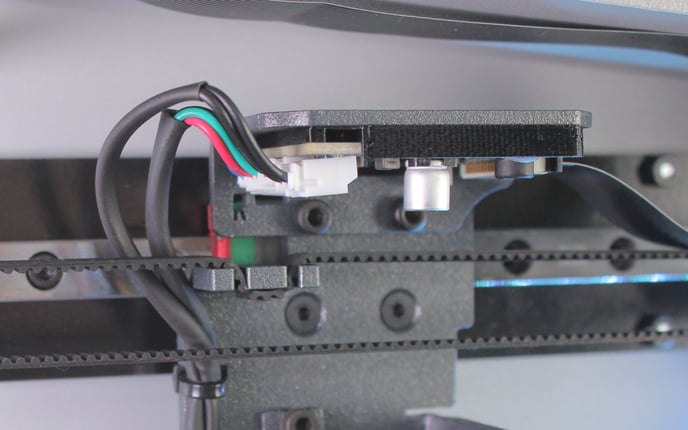

Checking Flat Cable Connection

Check if the flat cable is properly connected to the Y motor driver. If the connection is poor, the driver won't work correctly, causing the Y motor not move to the specified positions, in turn causing layers to not be aligned.

Checking Parallelism

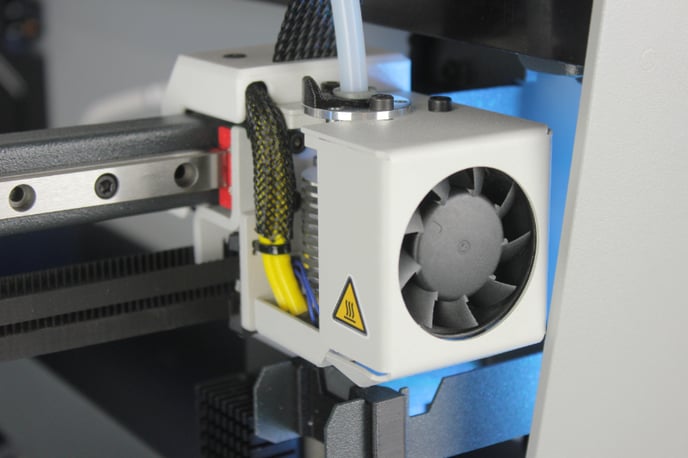

Place the printing heads on the sides of the carriage and bring the carriage to the front of the printer, so you can check the distance between the printing head and the printer structure on both sides.

If one of the printing heads is touching the frame before the other does, please contact the BCN3D Support team at this link: Contact us.

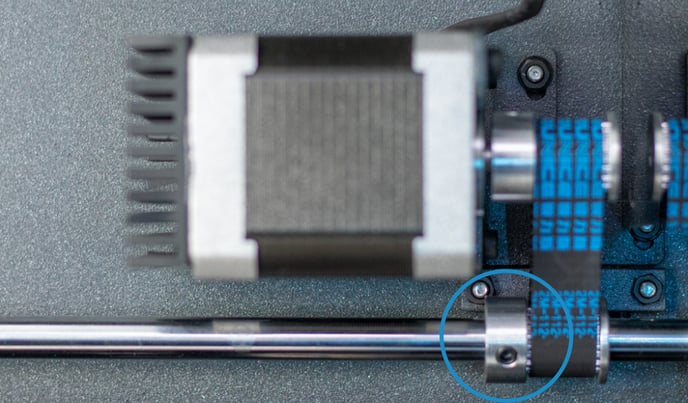

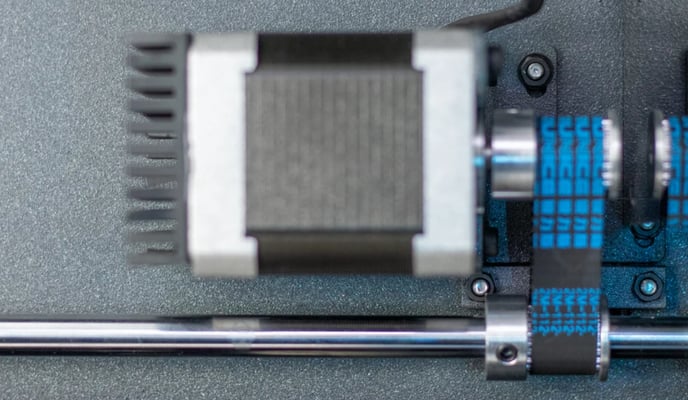

Adjusting Set Screws on the Y Smooth Bar Pulley

Note: If you hear a clicking noise coming from these pulleys, contact your reseller or the BCN3D Customer support team: Contact form.

Changing the Y Stepper Motor

If there’s mechanical resistance on the X carriage when manually moving it back and forth, the Y stepper may be blocked. Follow the next steps to check if the stepper motor is the problem:

1. Turn off and disconnect the printer.

2. Take out the belts from the Y axis holder and check its motion through the rails. If the Y carriage moves smoothly, the issue will most likely be on the stepper.

3. You can check the stepper resistance by manually rotating the pulley to see if it is blocked. Sometimes the driver can be the cause of this problem, so you should check the stepper motion after turning the printer off as well.

If the stepper motor is blocked you’ll have to change it for a new unit. To do this, continue to the following guide.

How to replace motor Y (Epsilon Series)

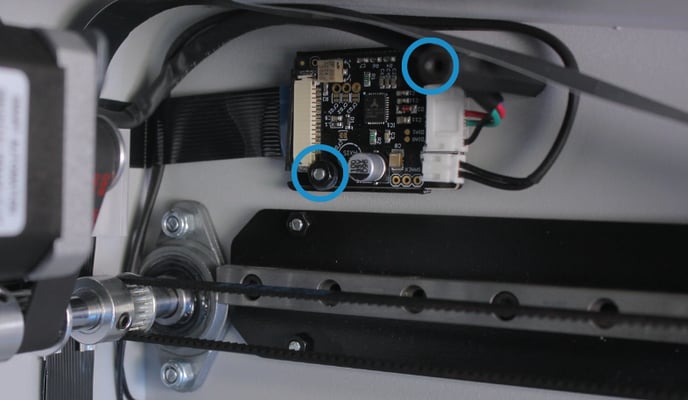

Changing the Y Driver

The driver board controls the Y motor. If it doesn't work correctly, the motor could behave abnormally, usually related to layer shifting. To check if the issue is being caused by the driver, follow the next steps:

1. Turn off and disconnect the printer.

2. Swap the Y driver for one of the X axis drivers.

Note: If you want more details about how to swap or change the drivers, please check the following guide: How to replace the X, Y and Z drivers (Epsilon Series)

3. Try to print and check if the problem continues, if the problem is solved, you will need to get a new driver to replace the faulty driver.

Forum Community

This article doesn't fix your issue? Check out our forum community for more info about this

It's important to keep your printer in good shape to make the most out of it. In this chart you can find a list of the extruder maintenance procedures and how frequently these should be done.

Maintenance Plan (Epsilon Series)

![]() Take your e-waste to a certified recycler. Check how we do it in BCN3D.

Take your e-waste to a certified recycler. Check how we do it in BCN3D.