The following tips will help you improve PA (Nylon) print quality, reduce warping, and prevent print failures such as clogs.

Note: This article contains advanced information regarding PA. The default settings for our BCN3D PA have been tailored for good quality and reliable results, and are fully tested by our laboratory. These tips complement those settings to ensure the best quality in printing with PA.

1. Introduction to Polyamide or Nylon

PA (Polyamide), better known by its trade name, Nylon, is a flexible polymer with amazing durability and tensile strength. Its properties make this material useful for a wide range of fields; including the textile industry, automotive industry, kitchen utensils, tools and sportswear.

However, it is not an easy filament to print, but you'll be able to print extraordinarily resistant pieces if you have an understanding on how to do it. Below you will find some tips to assist you with Polyamide (Nylon) printing.

Remember to check the compatibility of materials in case you are going to print parts that need to be manufactured with PA and another 3D printing filament.

2. Tips to improve printing with PA (Nylon)

Tip 1: Store it well

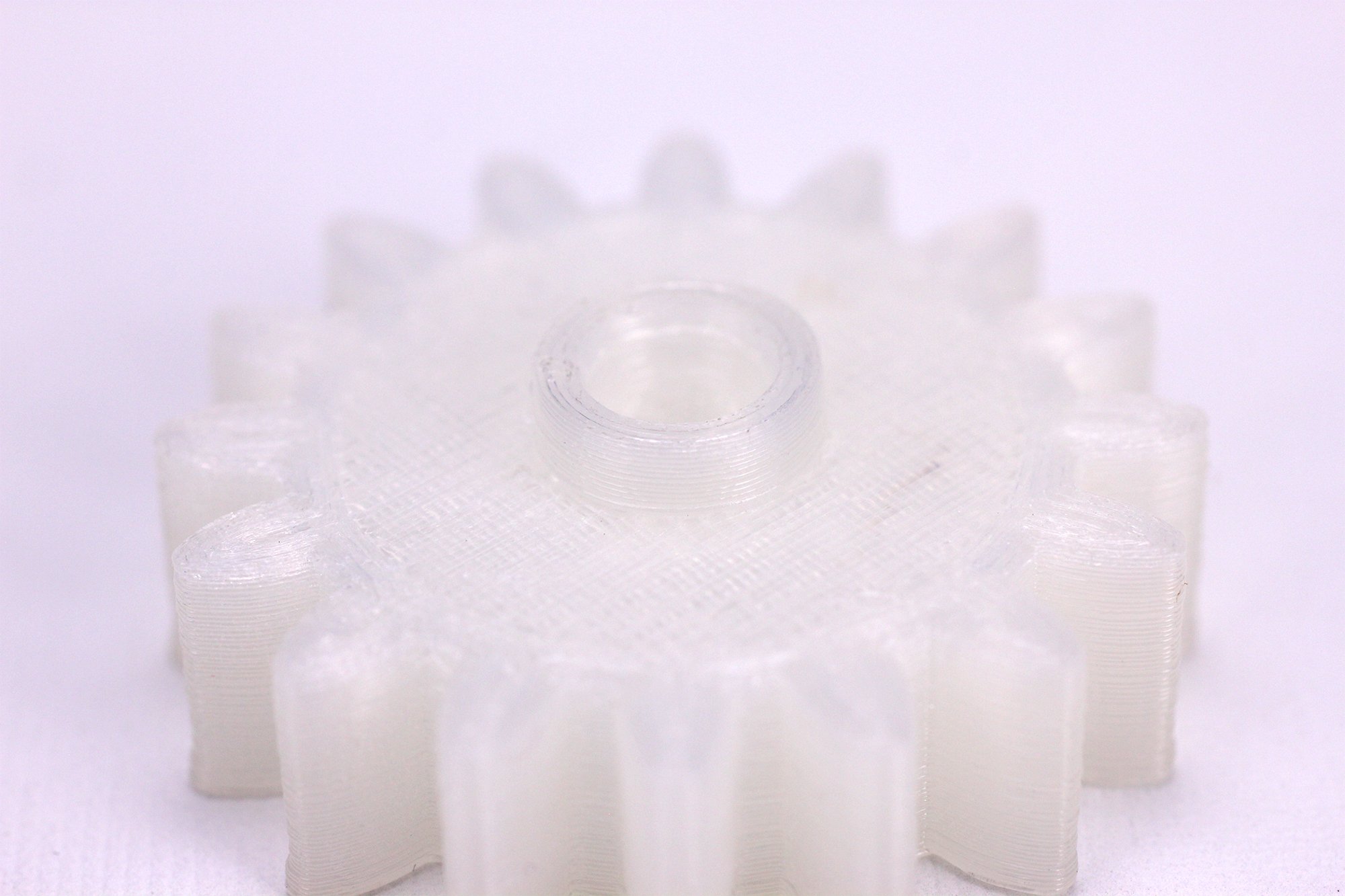

Nylon is highly hygroscopic, which means it absorbs moisture from the environment and quite quickly. When this happens, the polymer chains of PA break as the material heats up, making it weaker. This can cause moisture-related printing issues such as the final part not being as strong as desired and having a poor surface finish.

Note: If you print natural color Nylon (translucent) you will notice if it is wet when the filament comes out with a white hue. The remains of burned material on the part are also a sign that the PA is wet.

As an extra tip, for long prints, add a silica desiccant bag inside the PA spool, to avoid moisture in the filament.

Make sure to store the Nylon coils correctly in a dry and dark place, such as the BCN3D Smart cabinet or a cupboard.

Tip 2: Adjust settings to avoid warping and cracking

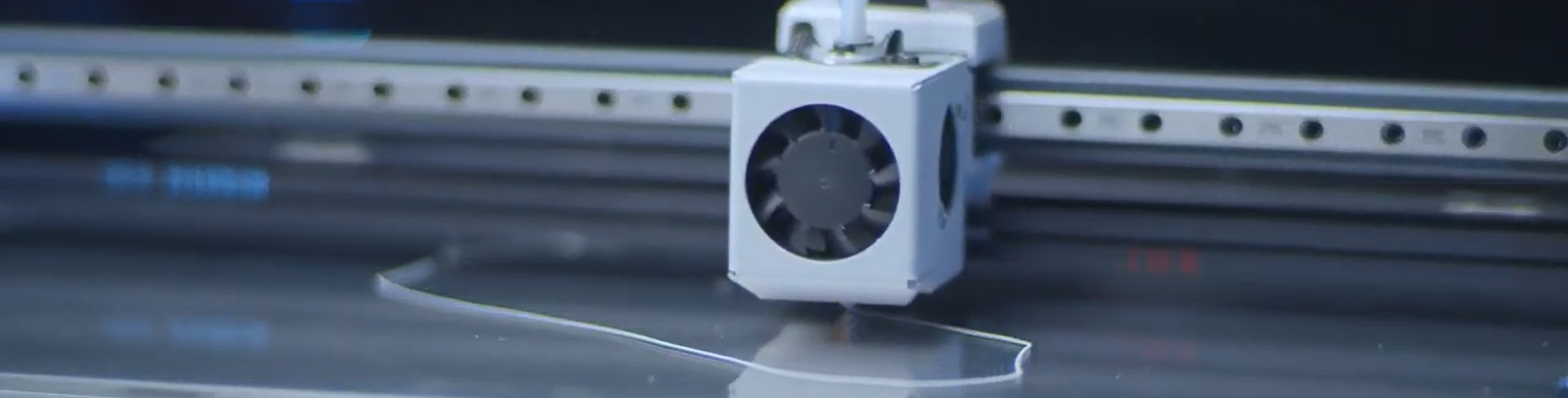

Nylon has a high shrinkage rate, which means that it shrinks a lot when it cools down, causing the print to warp and create cracks. To prevent this from happening, Nylon should be printed in a closed, warm environment, without refrigeration.

Since warping is caused by stress in the bottom layer of the part, the way to prevent Nylon from warping is to reduce the amount of material and increase the contact area:

- Reduce the number of undercoats from 3 to 2 coats.

- Reduce the number of perimeters from 3 to 2 perimeter lines.

- Use the edge as adhesion to the printing surface.

When printing large models with large diameter nozzles, in order to avoid delamination and cracking you must increase the temperature (5 or 10ºC more than the recommended value) and the print flow rate, as well as reduce the printing speed (10 or 15mm/s less than the recommended value).

Tip 3: Improve first coat adhesion

The first layer is very important when printing Nylon. A good Z-axis calibration is essential for success in printing and avoiding problems related to the first layer:

- If the Nylon is printed too far from the print surface, it will cause the part to suffer from warping, delamination and layer displacement.

- On the other hand, if it is too adherent to the printing surface, the shrinkage of the material will create stresses that can cause some pieces of glass to remain stuck on the part.

Applying a good amount of Magigoo PA and preheating the print surface for some time prior to printing helps reduce material tension, protects the print surface and generally prevents warping.

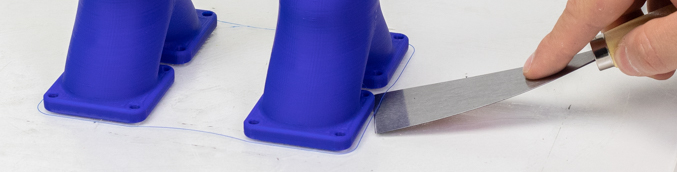

Tip 4: Safely remove the pieces

Before removing your parts from the printing surface, let it cool as slow as possible so it shrinks evenly and the tensions are eased. It is recommended to leave it inside the printer with the door closed.

Once cool, carefully remove the print. Apply a little water to dilute the Magigoo and avoid hitting the piece during its extraction.

Tip 5: Improve appearance and surface quality

BCN3D Nylon is translucent, which means that if you print with an infill it will be visible. If you want your pieces to look better, increase the line count of the wall and set the infill percentage to 0% when possible.

If your piece requires support structures, the ideal method is to use soluble materials for printing, because Nylon has very good adhesion between layers when printed under ideal conditions, which in turn makes it difficult to remove the supports.

Conclusions

- Nylon is a highly hygroscopic material which is why it is necessary to store it hermetically and dry it regularly.

- It is highly recommended to unload the material if it is not going to be used for more than two days and clean the hotend very well to avoid clogs.

- Reducing the number of perimeters and lower layers helps reduce stresses in the first layer, and thus warping.

- Setting the edge to the build surface bond reduces the chance of the part warping.

- Check the first layer and adjust the calibration in the Z axis to ensure that the polyamide is correctly adhered to the printing surface.

- Let the part cool slowly inside the printer before removing it from the print surface to avoid warping or damage to the print surface.

- In the case of having to print with supports, it is advisable to use soluble support materials, since Nylon supports are very difficult to remove.